¶ Solid-Phase Synthesis

When synthesizing biopolymers, a lot of steps will be involved. It is therefore crucial for the synthetic process to fufill the following requirements

- High yield reaction steps

- High excess of reagents to help increase the yield

- Cheap building block, so it is not costly to use a high excess of reagents

- Fast reactions

These conditions can be satisfied with Solid-Phase Synthesis

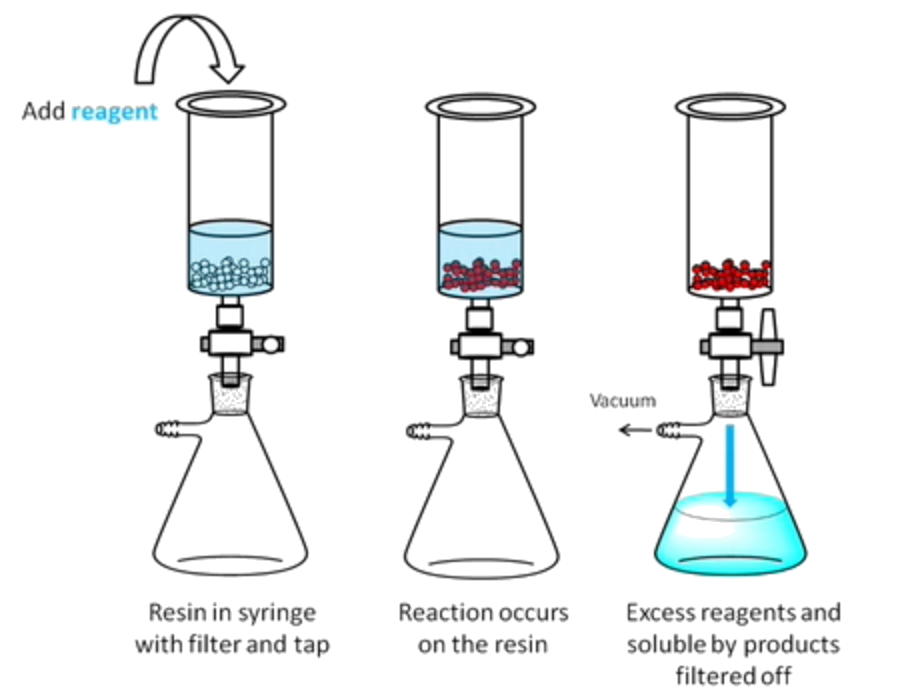

Principle of Solid-Phase Synthesis

We immobilize our reactant on a solid-support, called a resin

- In biopolymers, this is where we grow our polymer chain

We put our resin in a vessel such that when a vaccum is applied, reagents that are not attached to the resin can be removed

- The resin is washed with solvent in between each step to ensure the excess reagents are removed

- No work-up or purification is needed in between each steps, which results in a higher yield

- Unlike solution synthesis, we do multiple steps in a row without characterization

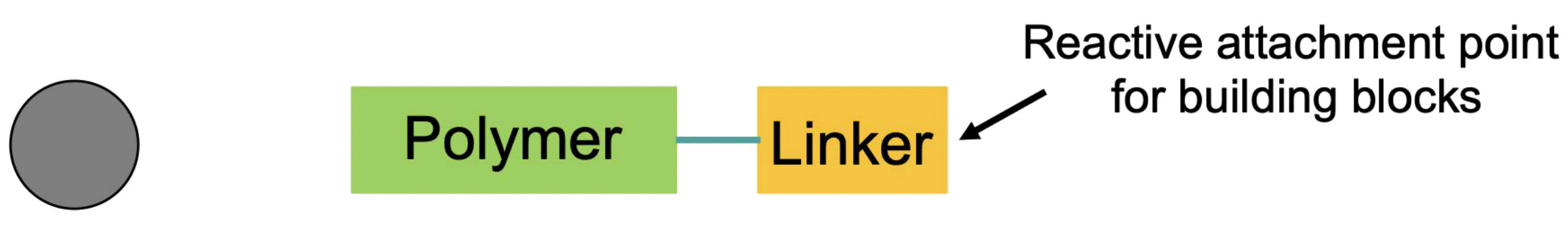

Resins

Resin beads are usually made of inert polymers like polystyrene or polyamide

- The beads must be inert to all the coupling reagents that will be used in the reaction

- The bead must swell in solvent so that it can allow reagents to get through the holes to come into contact with the reactants that have been attached to the resin

- The resin polymer must be functionalized with a reactive handle ( aka linker ) to allow us to immobilize our first reagent to the resin

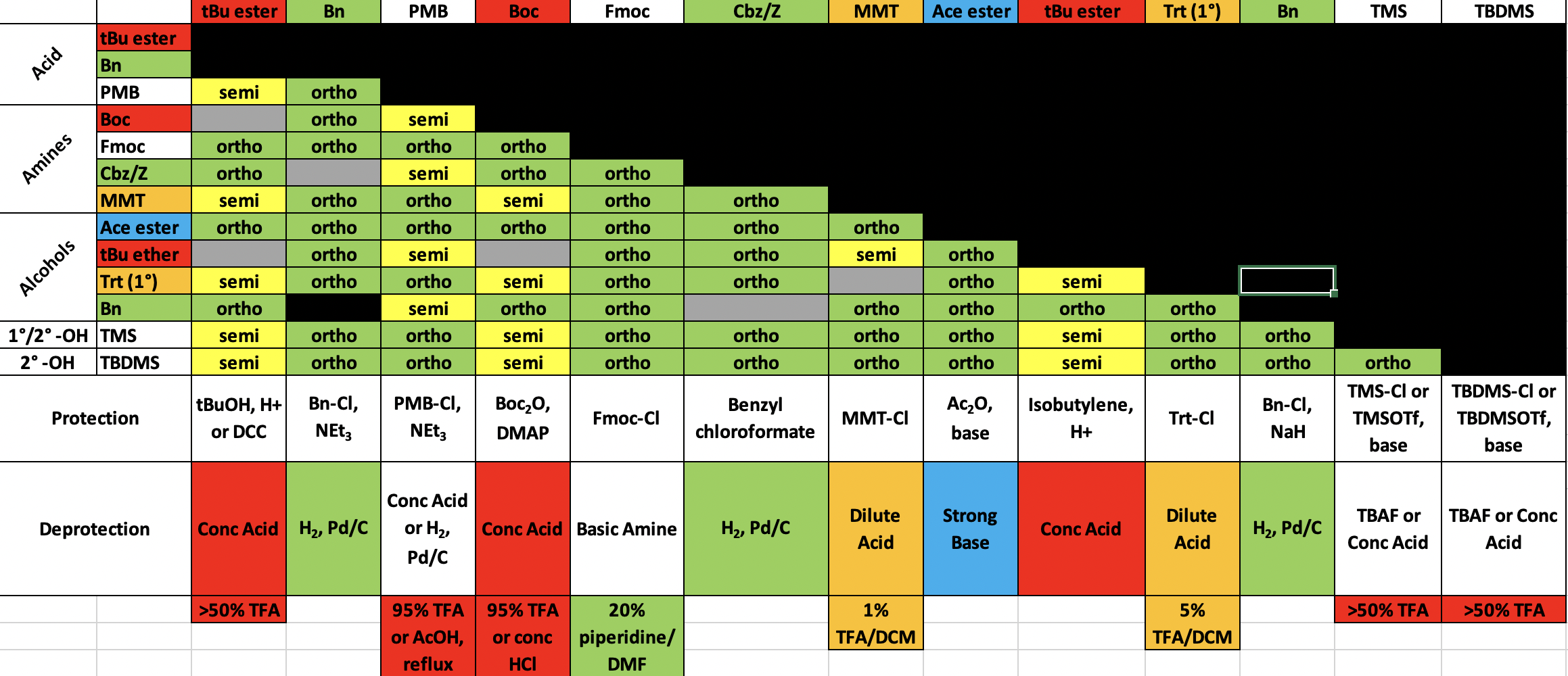

¶ Protecting Groups

Protecting groups temporarily mask specific functional groups in a molecule so other functional groups can be selectively transformed

- Protecting groups are commonly used when a specific functional group is vulnerable to the reagents or conditions necessary for a desired transformation

- The protecting group is then removed later in the synthesis to reveal the original functional group.

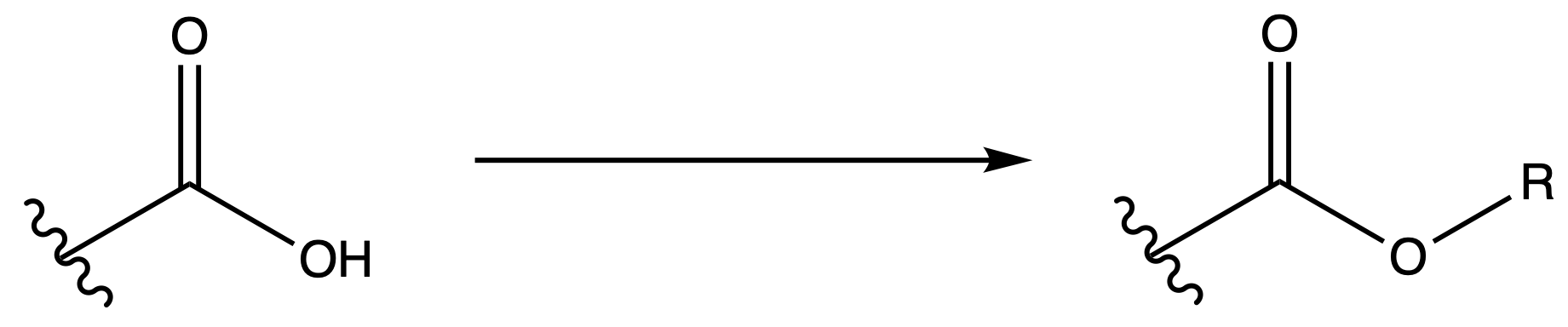

¶ Carboxylic Acids

We want to protect the carboxyl group so as to

- Avoid proton donation

- Nucleophilic attack

- Enolisation

We can achieve this by converting the carboxyl group into a bulky ester group such that the steric hinderance will kinetically prevent reactions

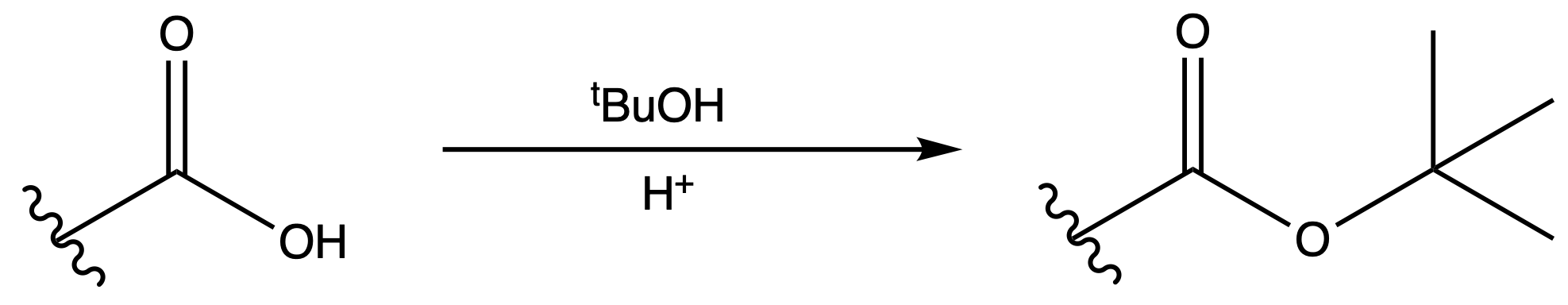

Tertbutyl Esters (tBu)

Protection

Reagents needed:

- tBu–OH + H+

or- tBu–OH + DCC

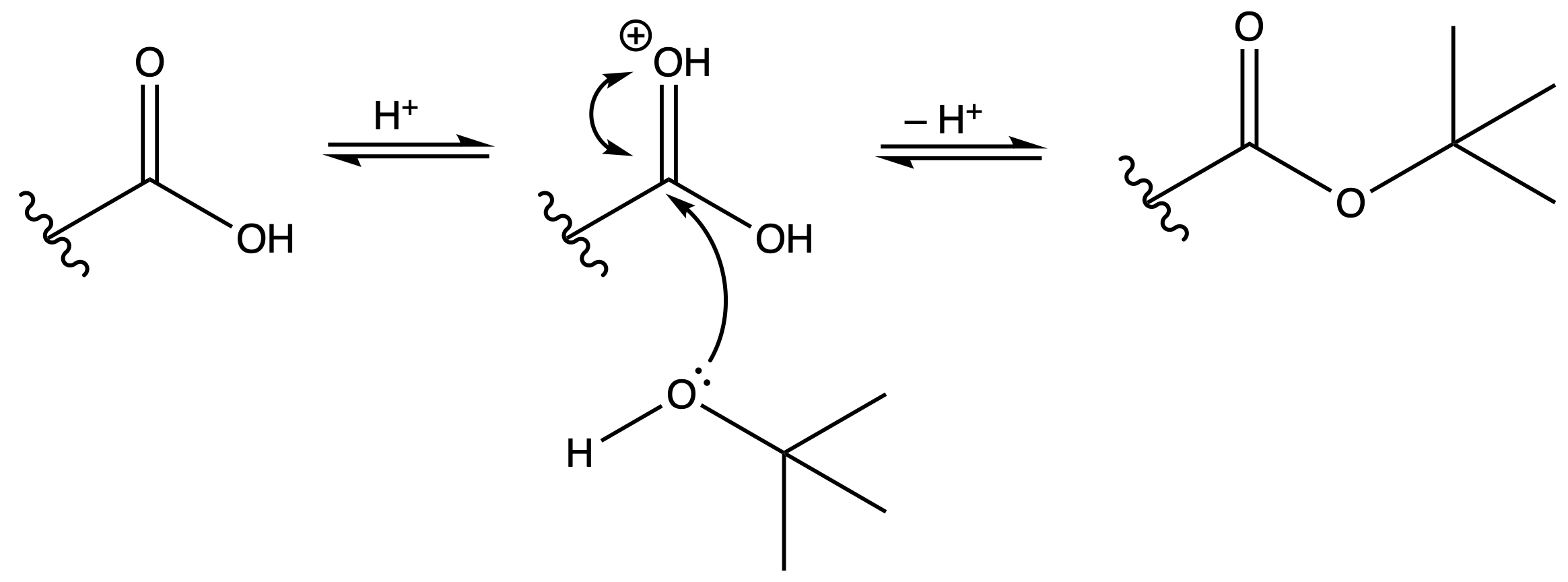

Mechanism :

Deprotection

Reagents needed:

- Concentrated acid

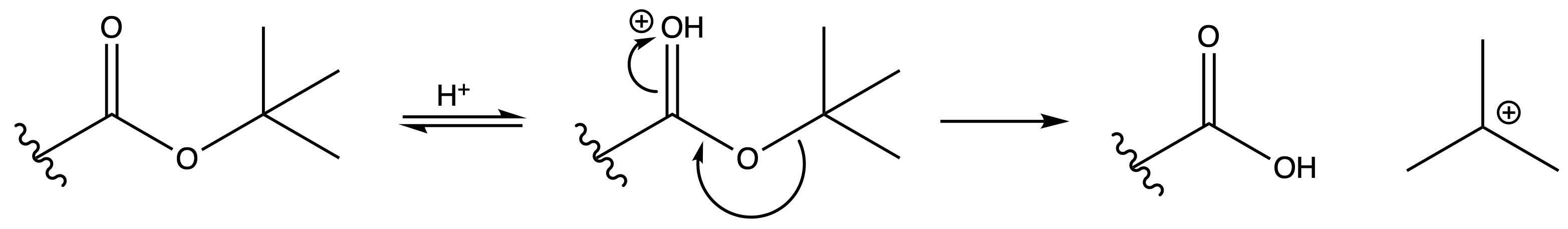

Mechanism :

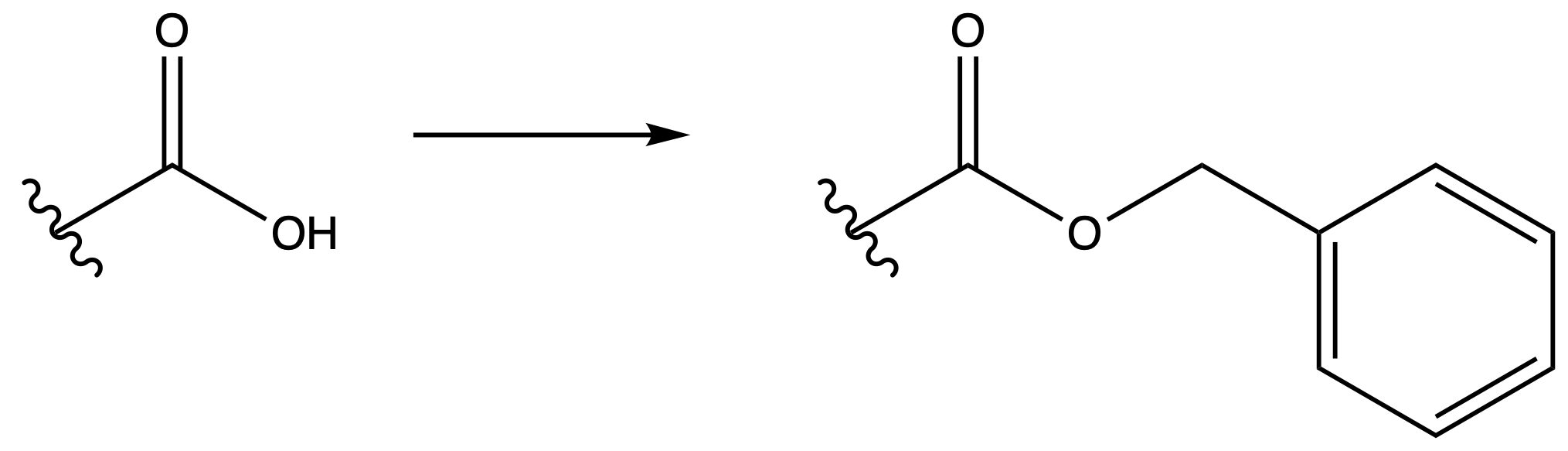

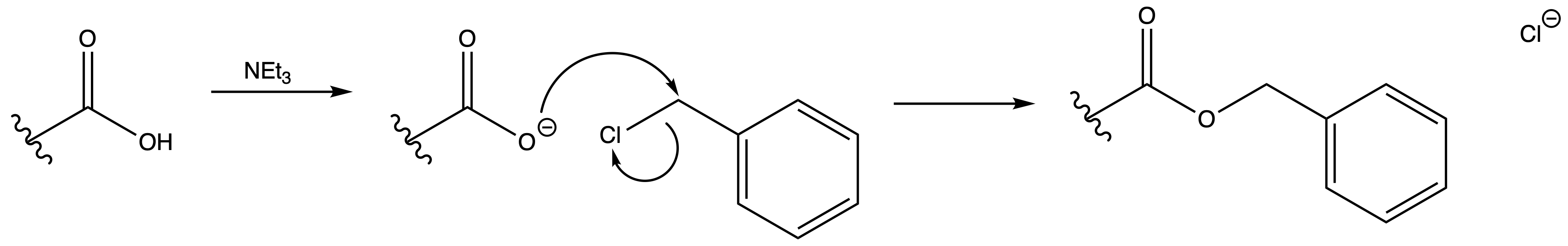

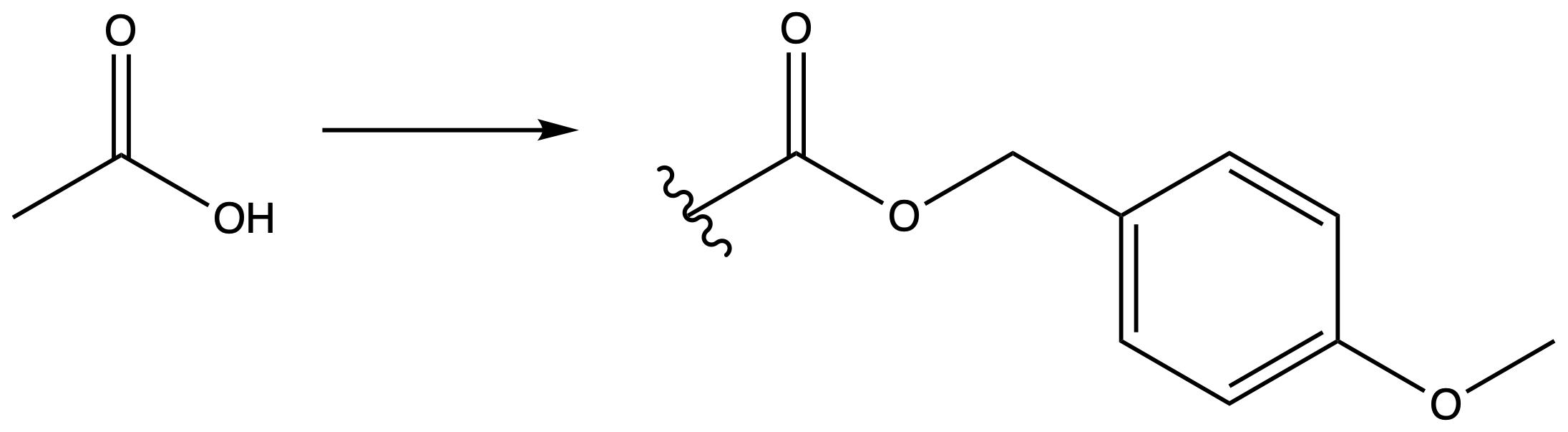

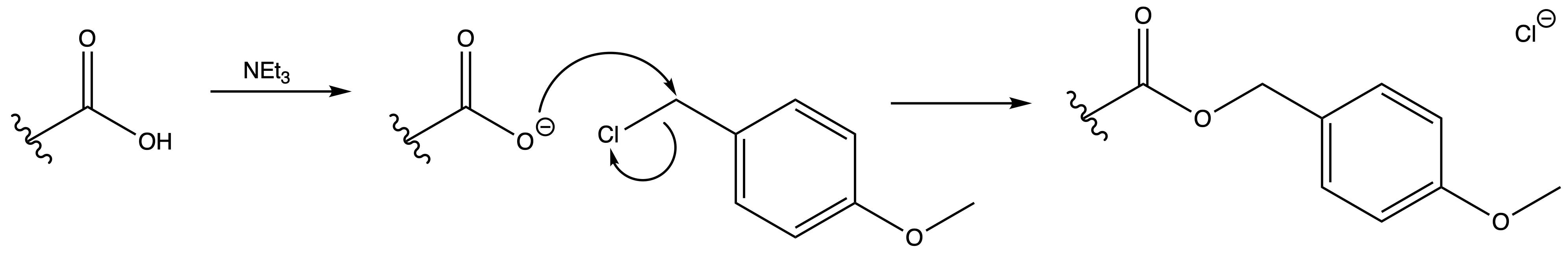

Benzyl ester (Bn)

ProtectionReagents needed:

- Bn-Cl + NEt3

Mechanism :

Deprotection

Reagents needed:

- H2 + Pd/C

4-Methoxybenzyl Ester (PMB)

ProtectionReagents needed:

- PMB-Cl + NEt3

Mechanism :

Deprotection

Reagents needed:

- Concentrated acid

or- H2 + Pd/C

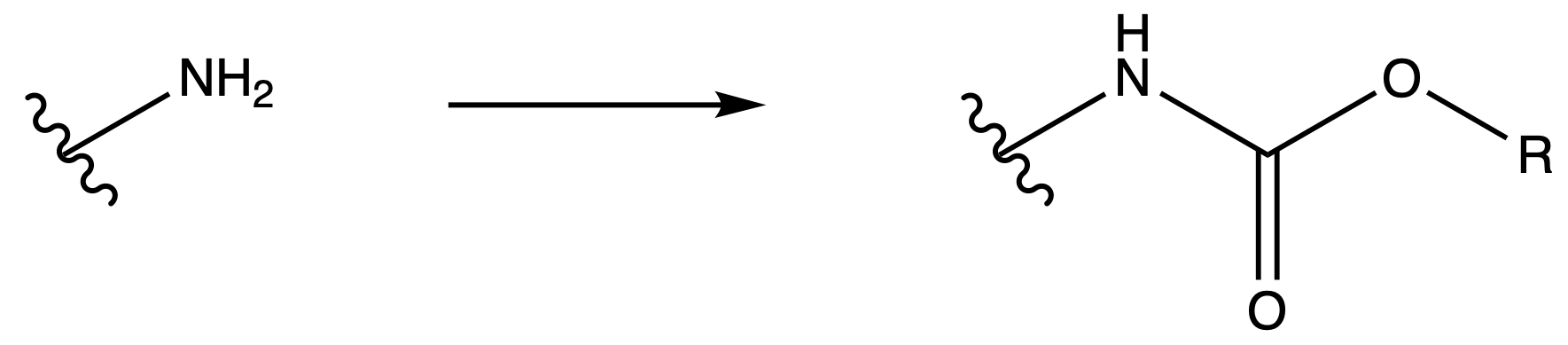

¶ Amines

We want to protect the amine group so as to

- stop the nitrogen from acting as a nucleophile

- stop the nitrogen from acting as a base

We can achieve this by converting the amine group into a carbamates group such that the steric hinderance and conjugation will kinetically and thermodynamically prevent reactions

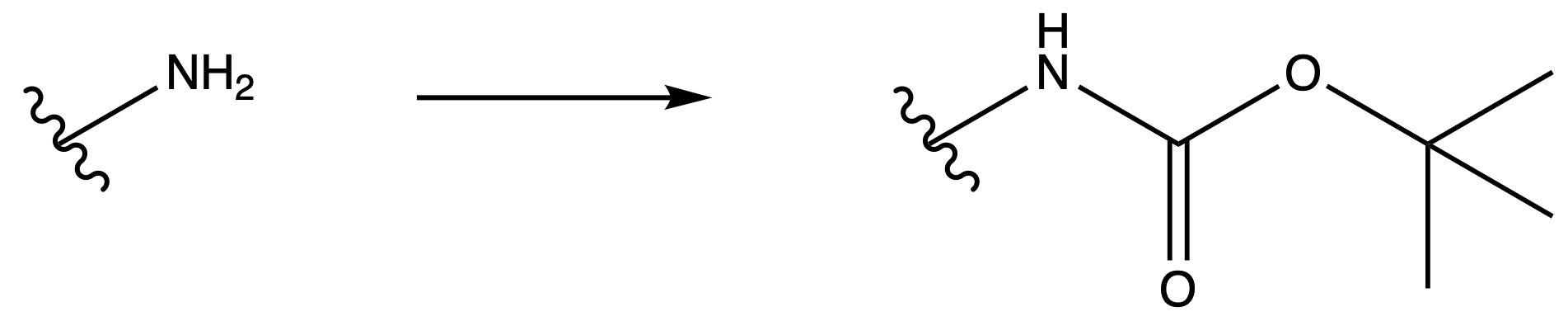

tert-Butyloxycarbonyl Carbamate ( Boc )

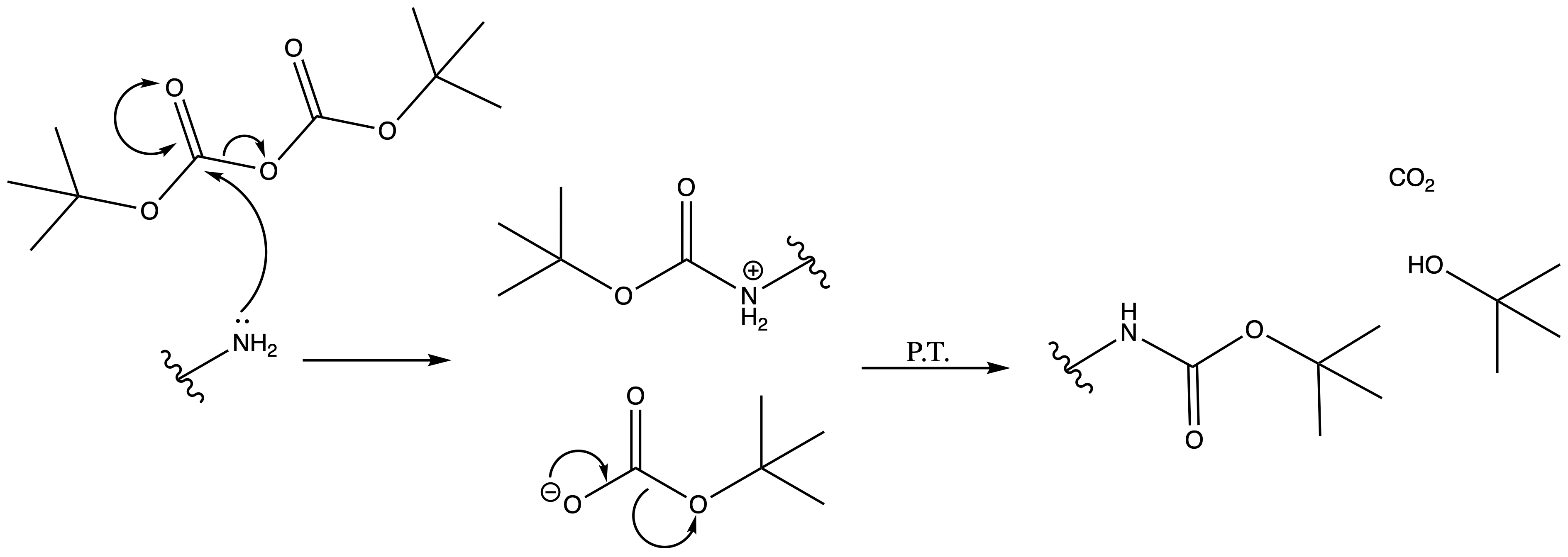

ProtectionReagents needed:

- Boc2O + DMAP

Mechanism :

Deprotection

Reagents needed:

- Concentrated acid

Mechanism :

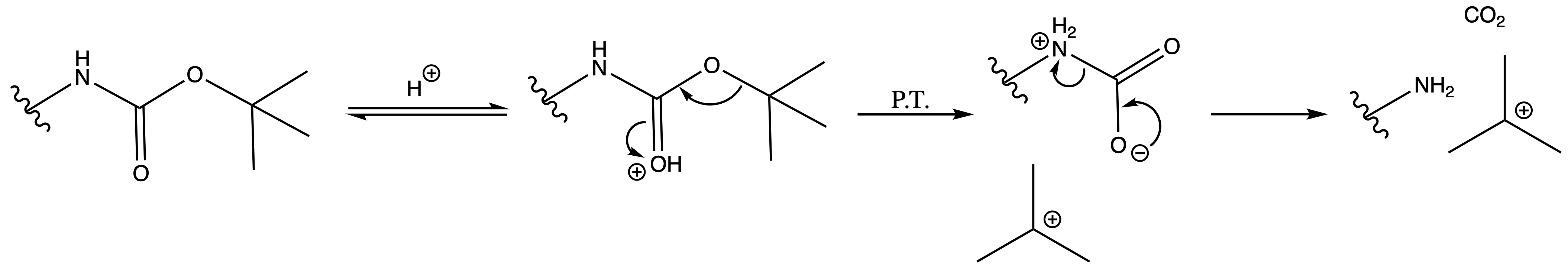

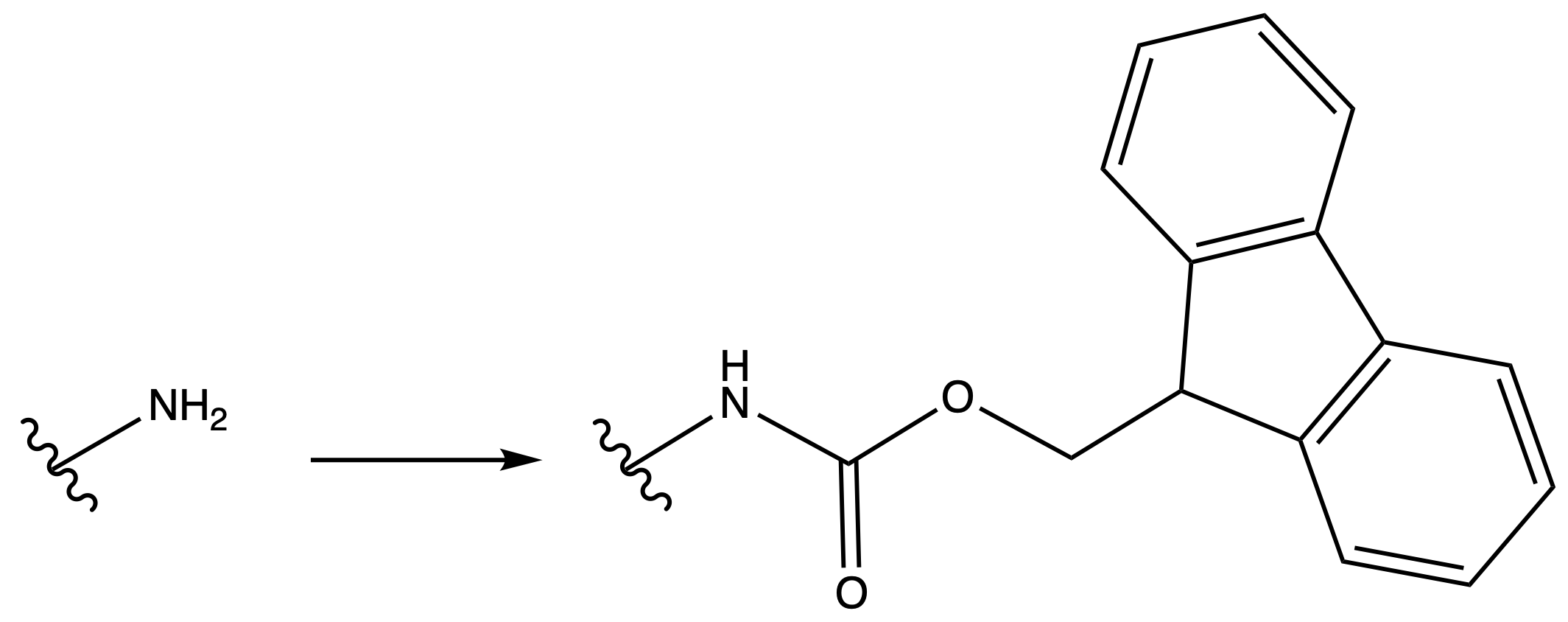

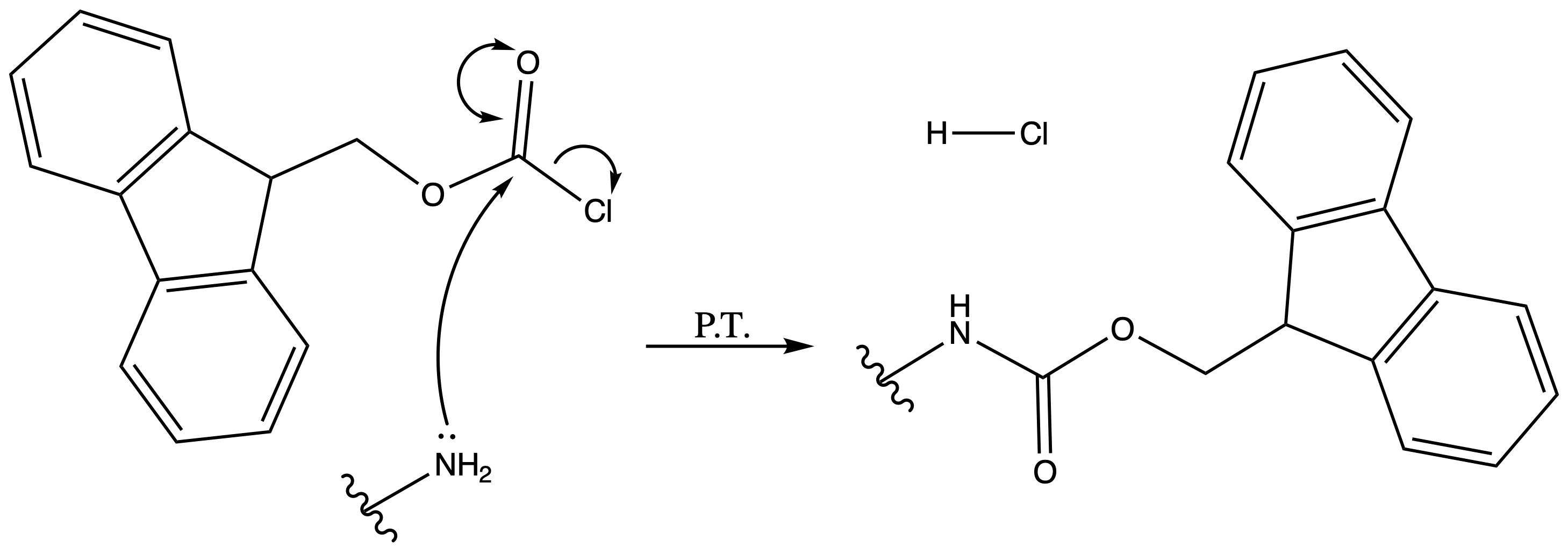

9-Fluorenylmethoxycarbonyl Carbamate ( Fmoc )

ProtectionReagents needed:

- Fmoc-Cl

Mechanism :

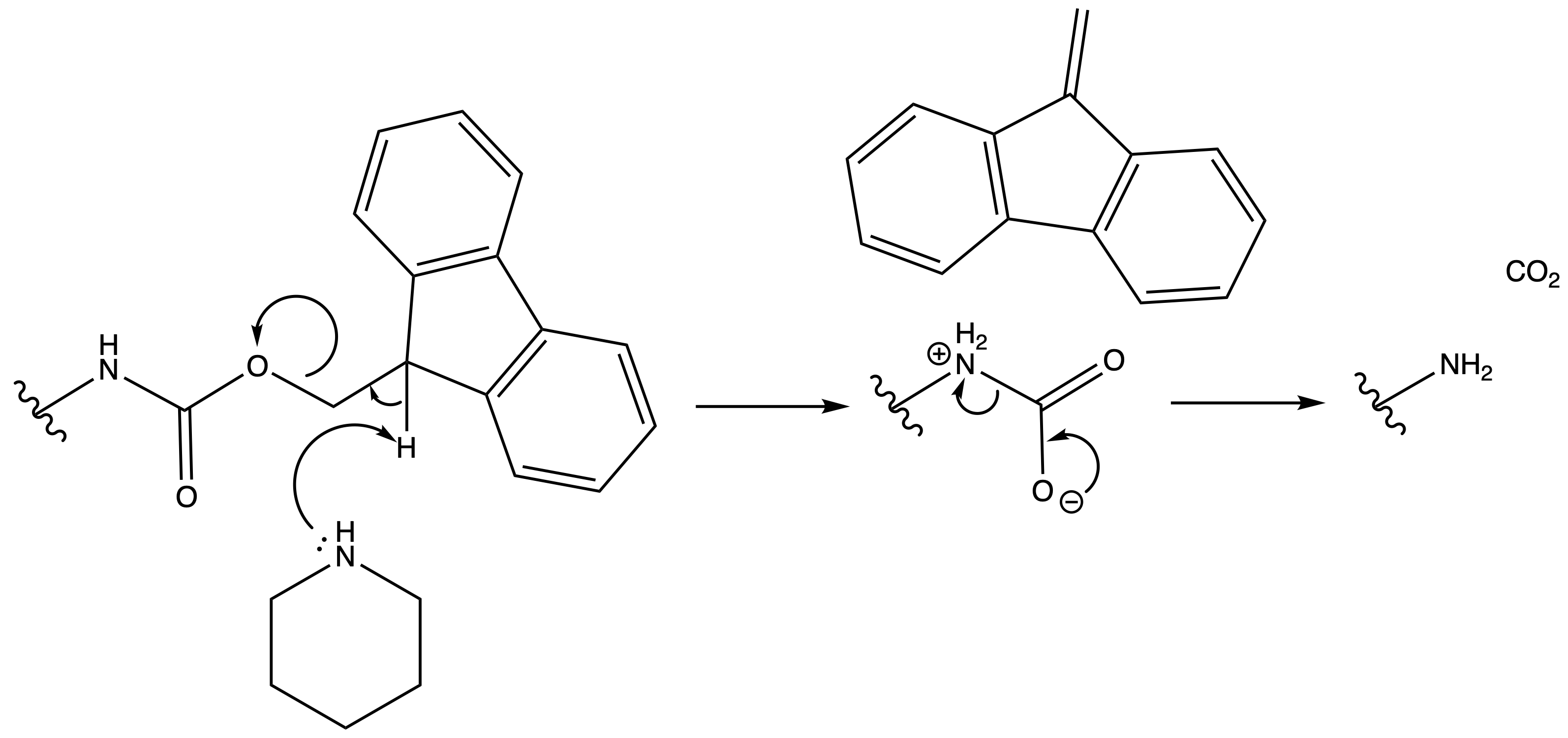

Deprotection

Reagents needed:

- Base

Mechanism :

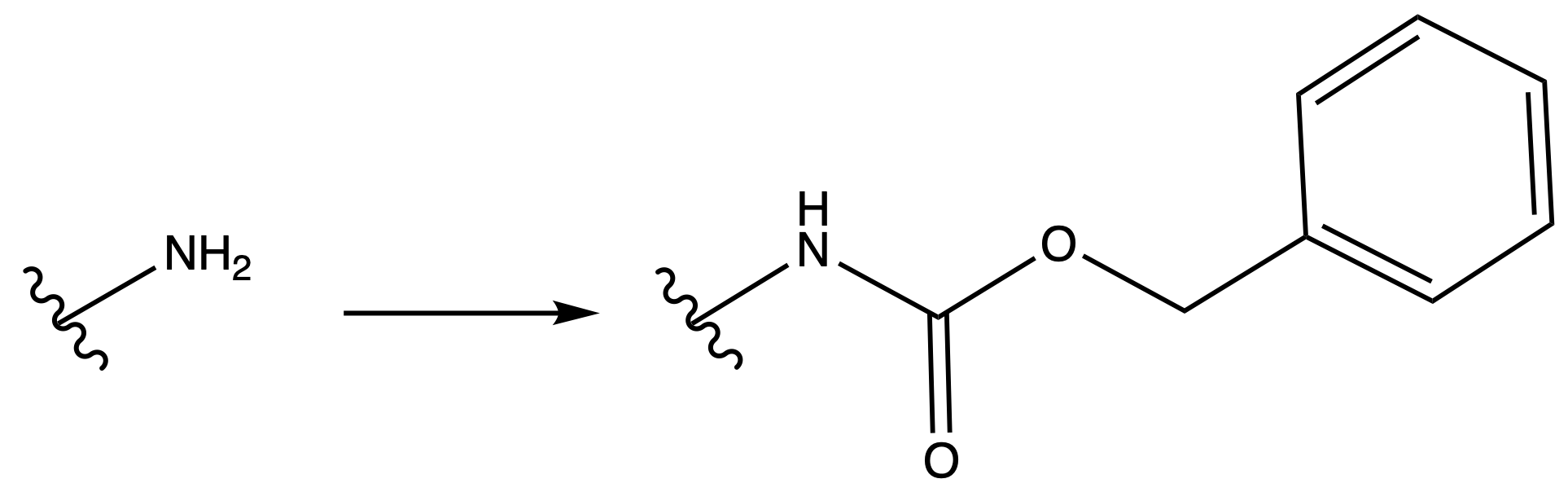

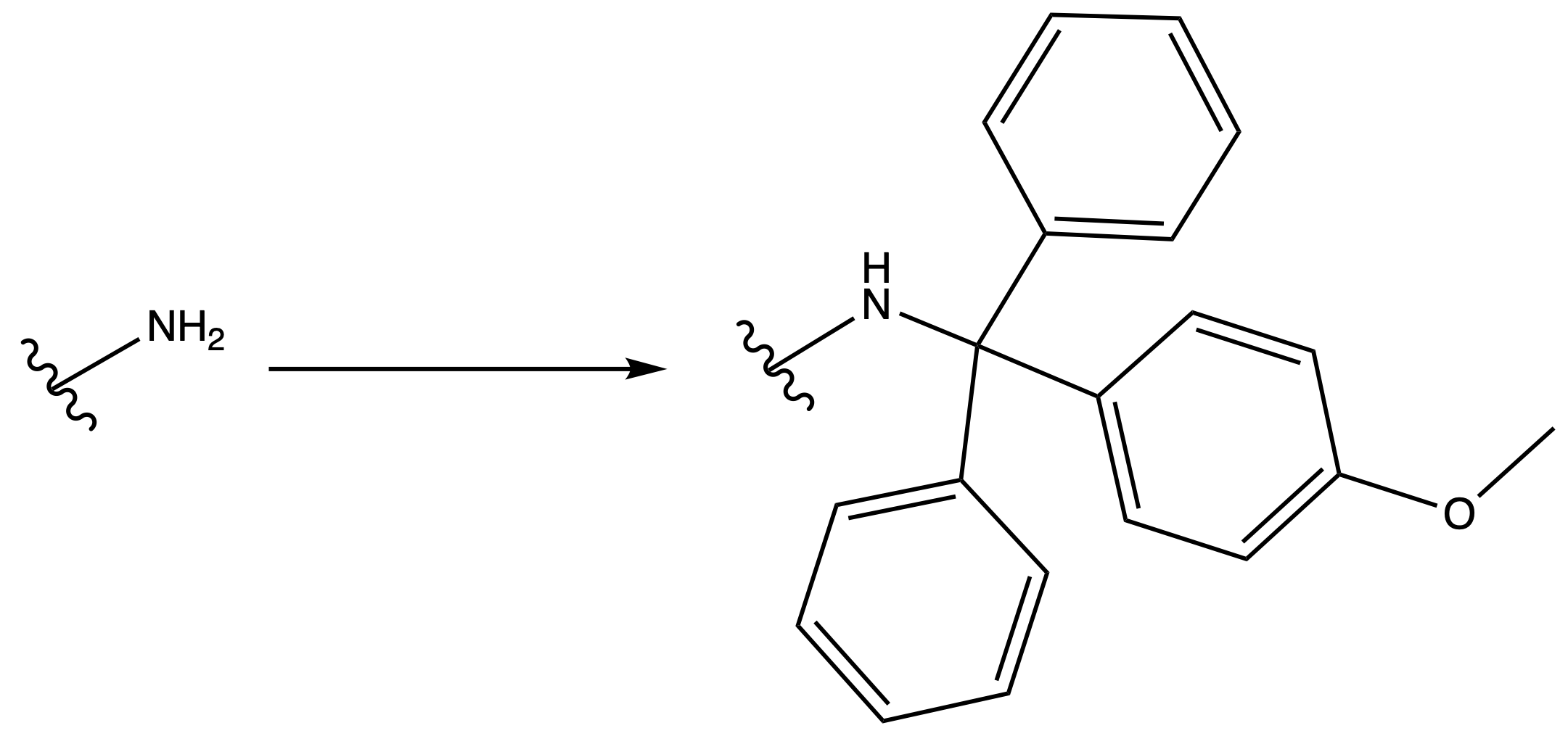

Carboxybenzyl Carbamate ( Cbz )

ProtectionReagents needed:

- Boc2O + DMAP

Mechanism :

Deprotection

Reagents needed:

- H2 + Pd/C

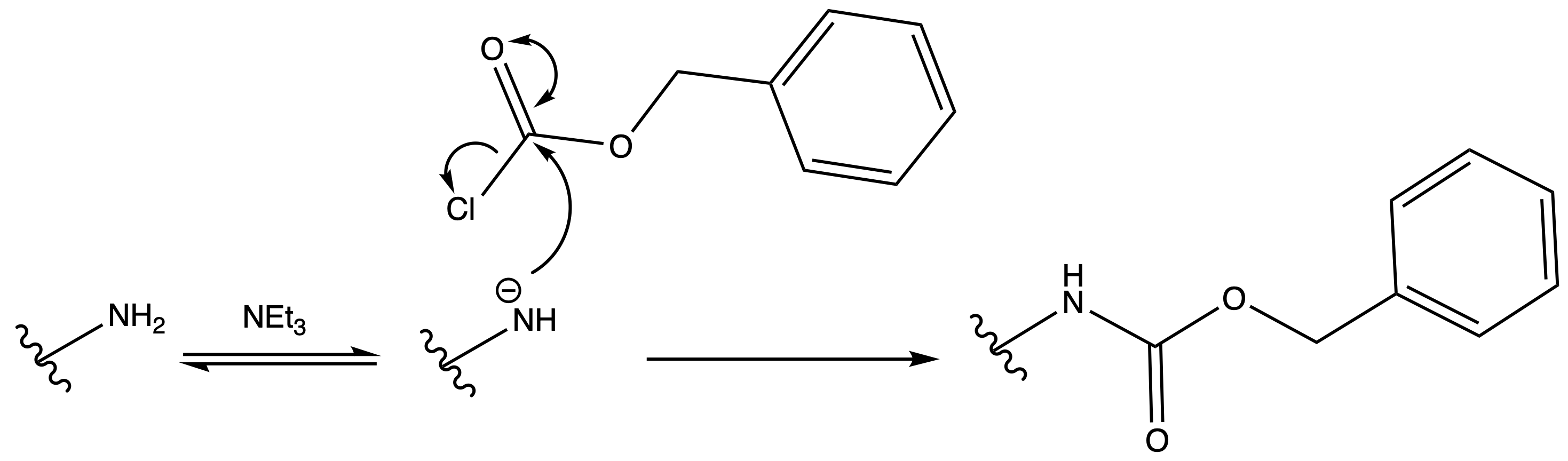

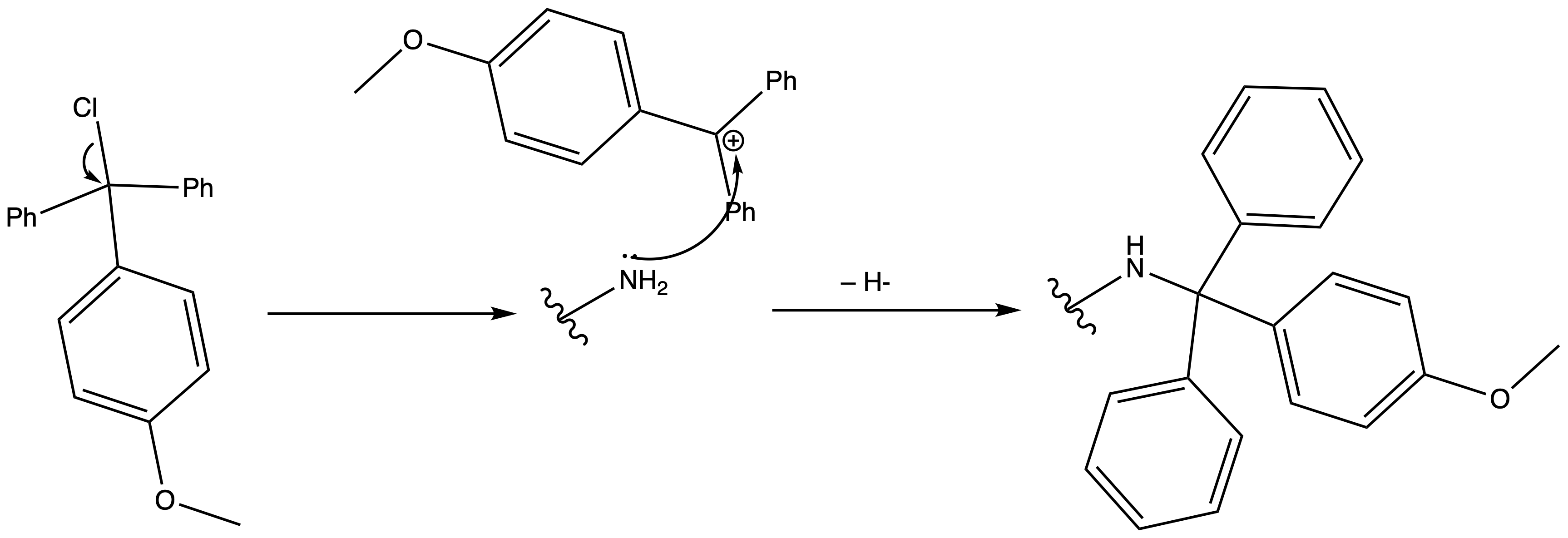

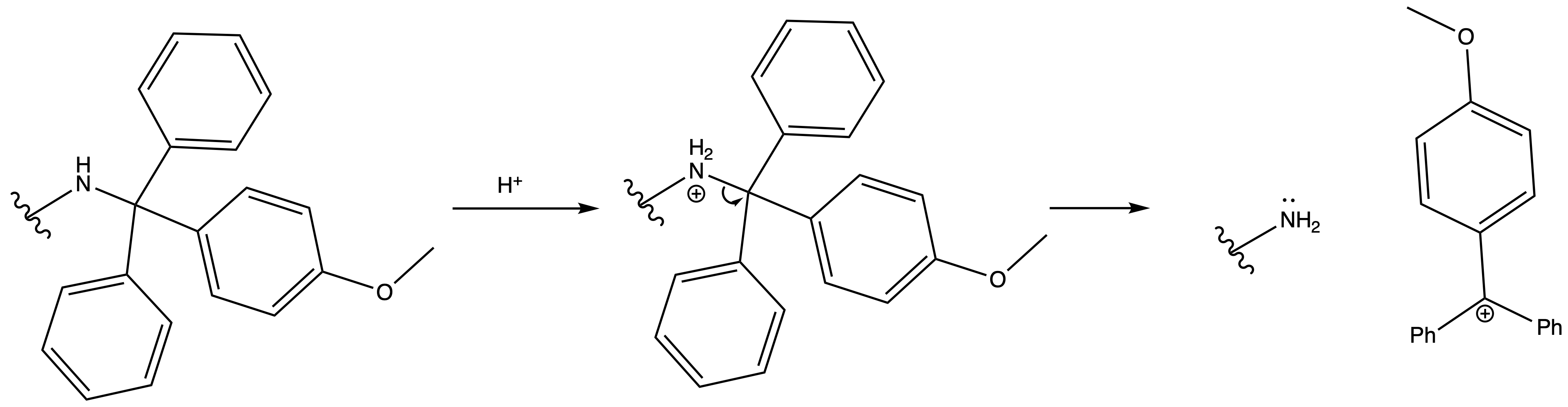

Monomethoxytrityl ( MMT )

ProtectionReagents needed:

- MMT–Cl

Mechanism :

Deprotection

Reagents needed:

- Concentrated acid

Mechanism :

¶ Alochol

We want to protect the amine group so as to

- stop the oxygen acting as a nucleophile,

- prevent oxidation

- proton donation

We can achieve this by introducing steric hindrance or conjugation

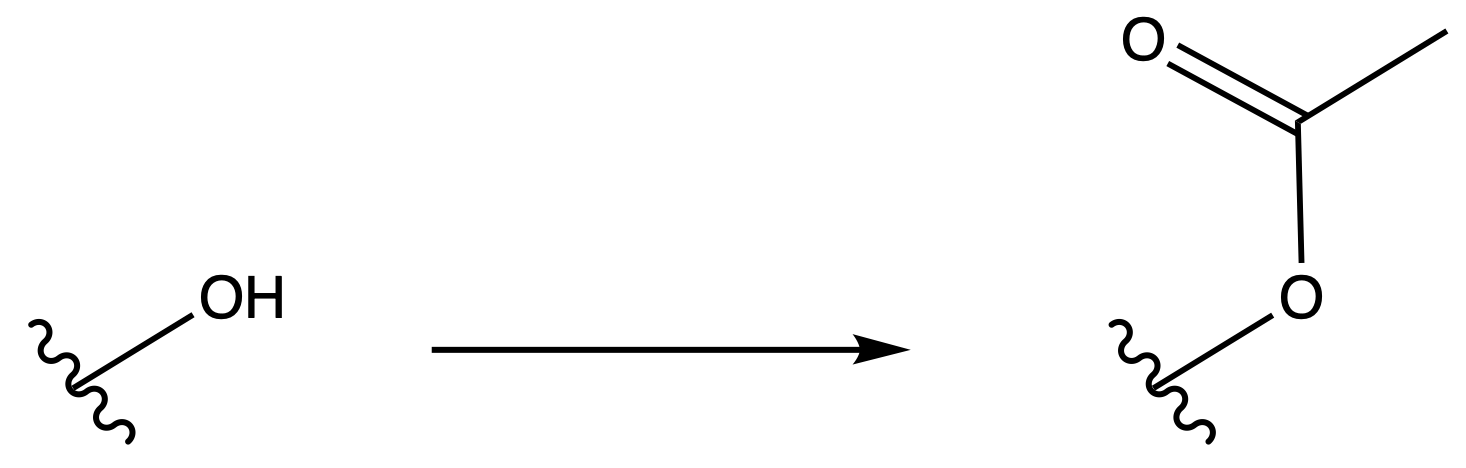

Ester

ProtectionReagents needed:

- Ac2O + Base

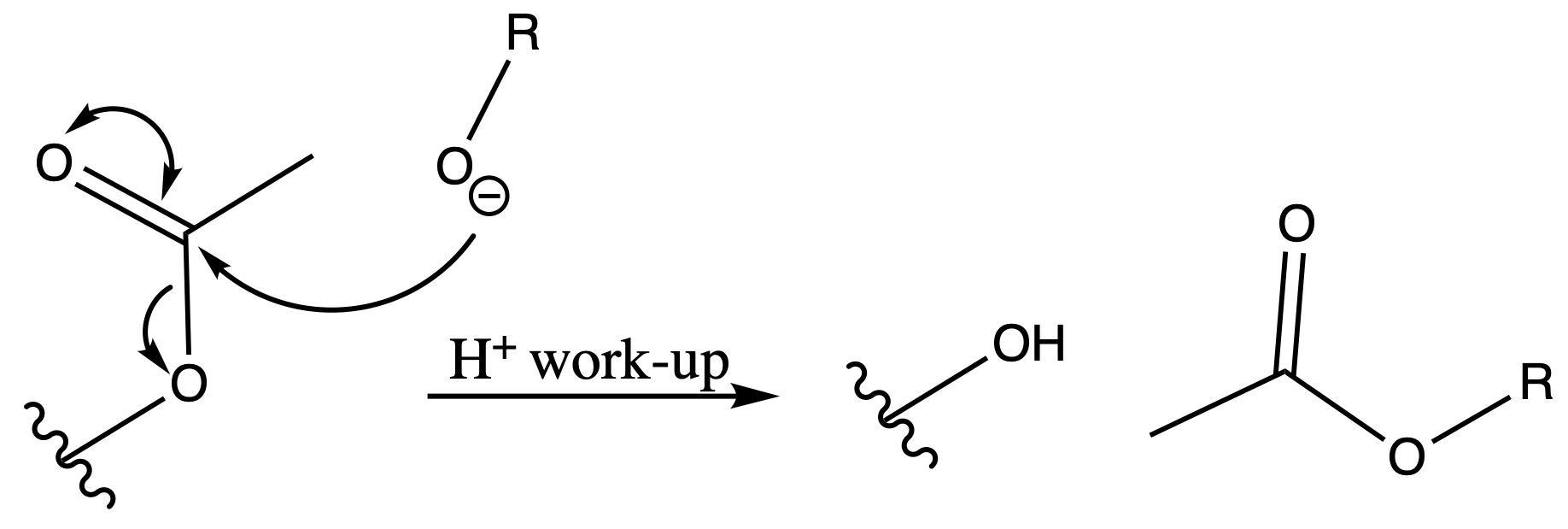

Mechanism :

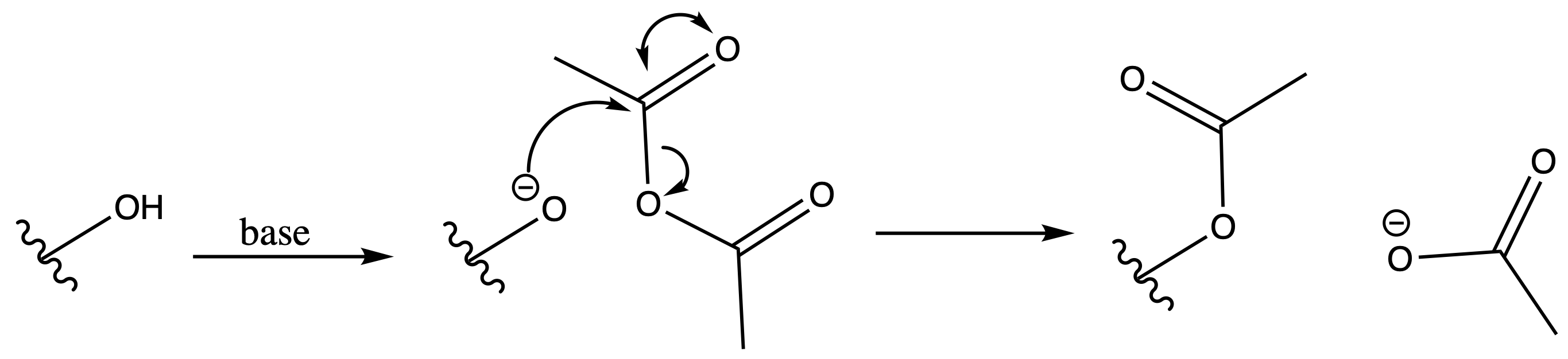

Deprotection

Reagents needed:

- Strong Base

Mechanism :

¶

tert-butyl Eter

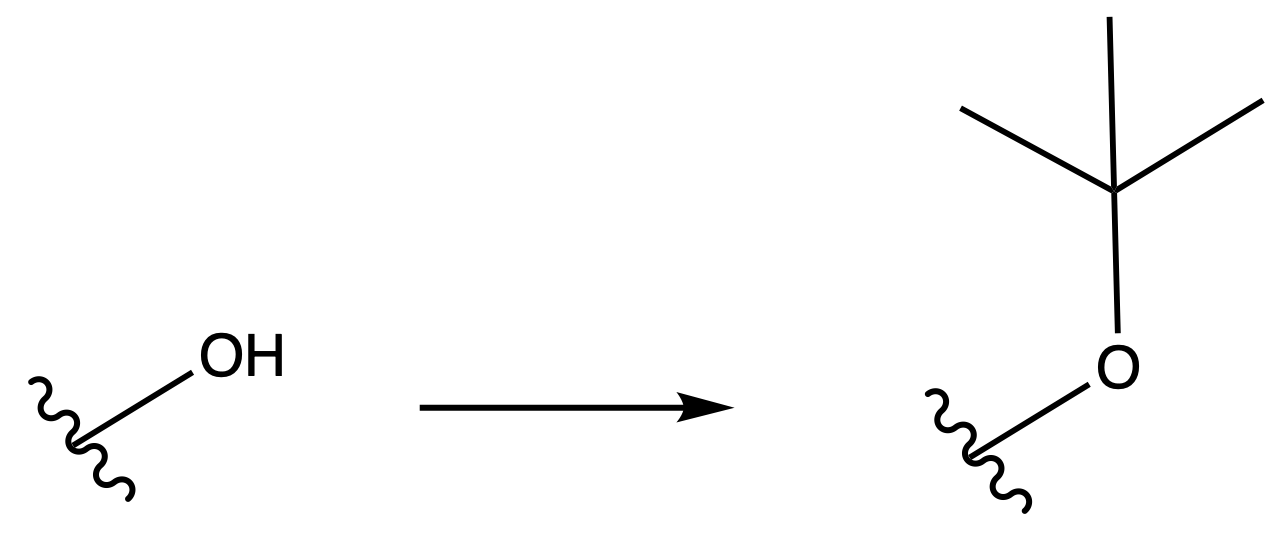

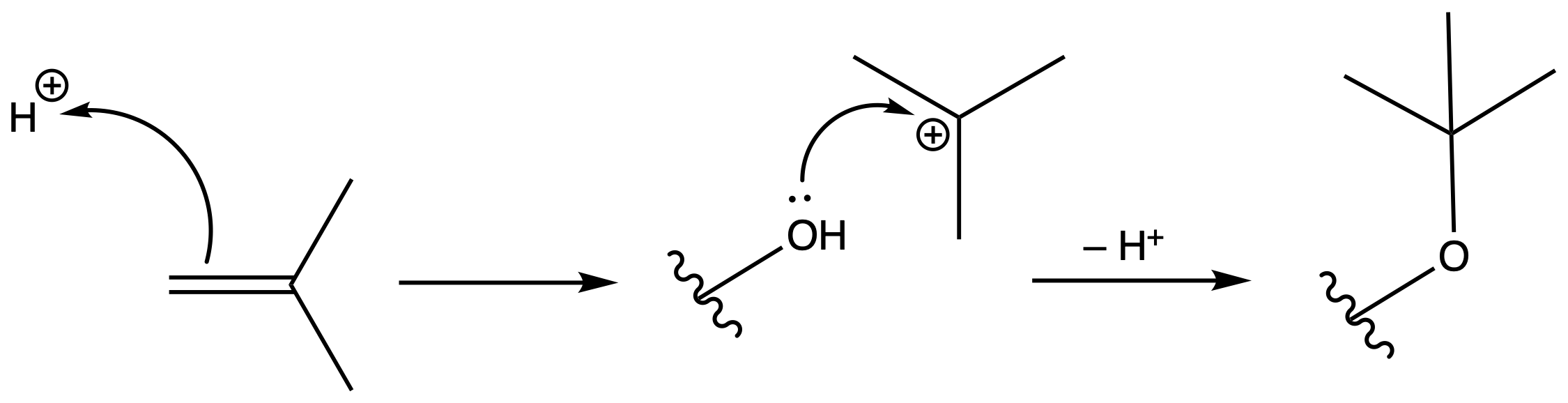

ProtectionReagents needed:

- Ac2O + Base

Mechanism :

Deprotection

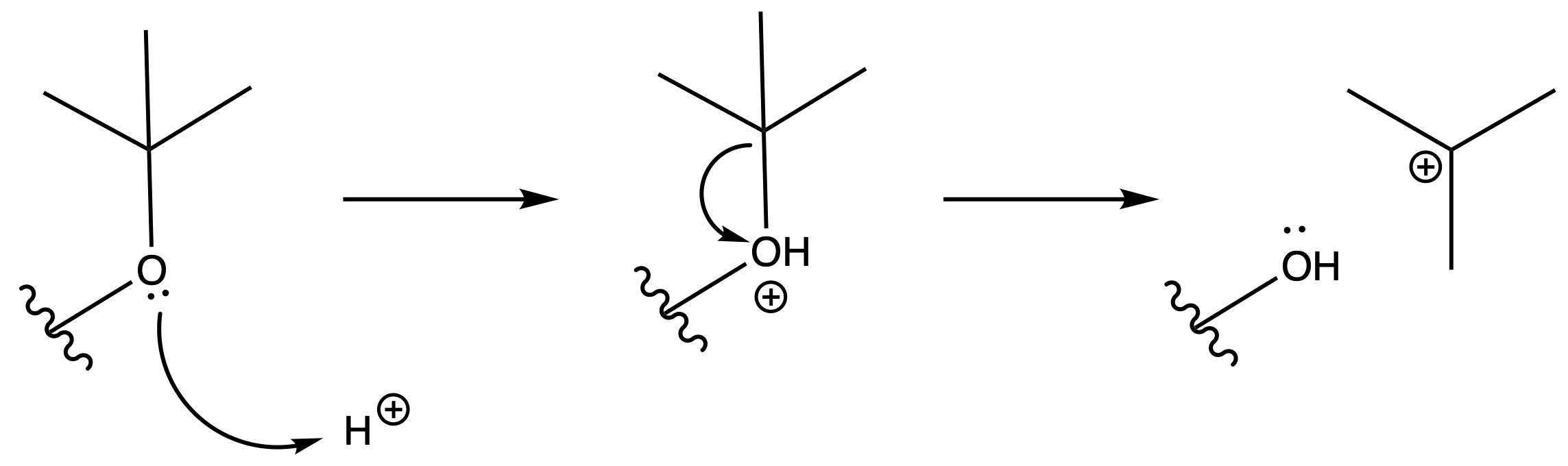

Reagents needed:

- Concentrated Acid

Mechanism :

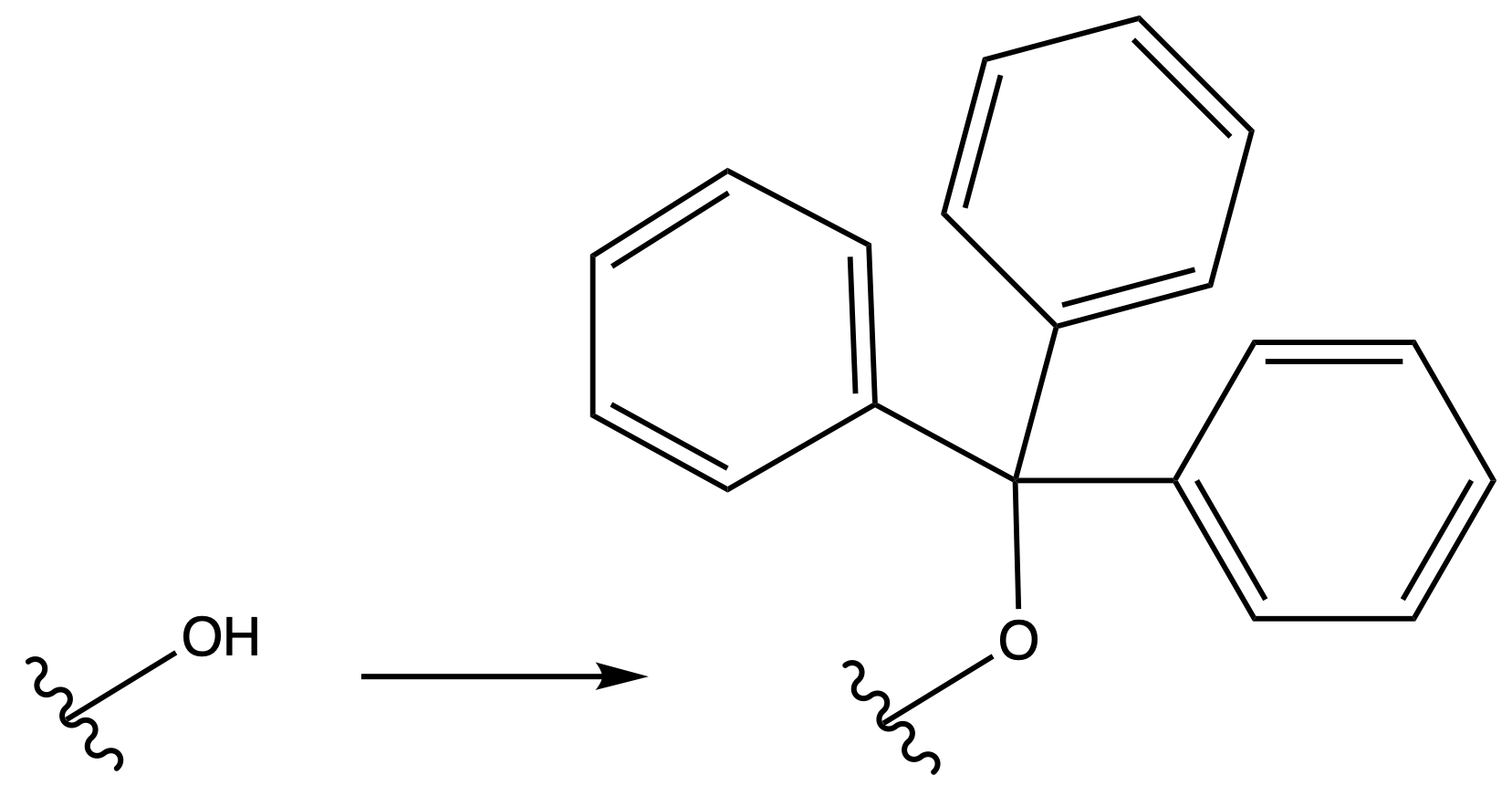

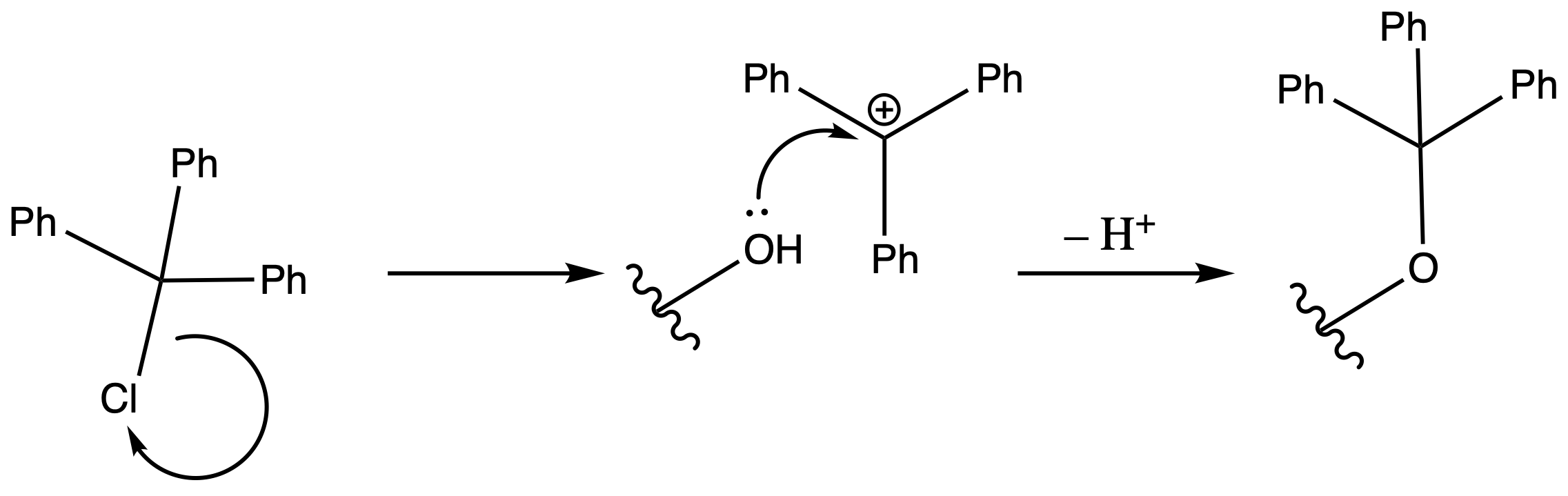

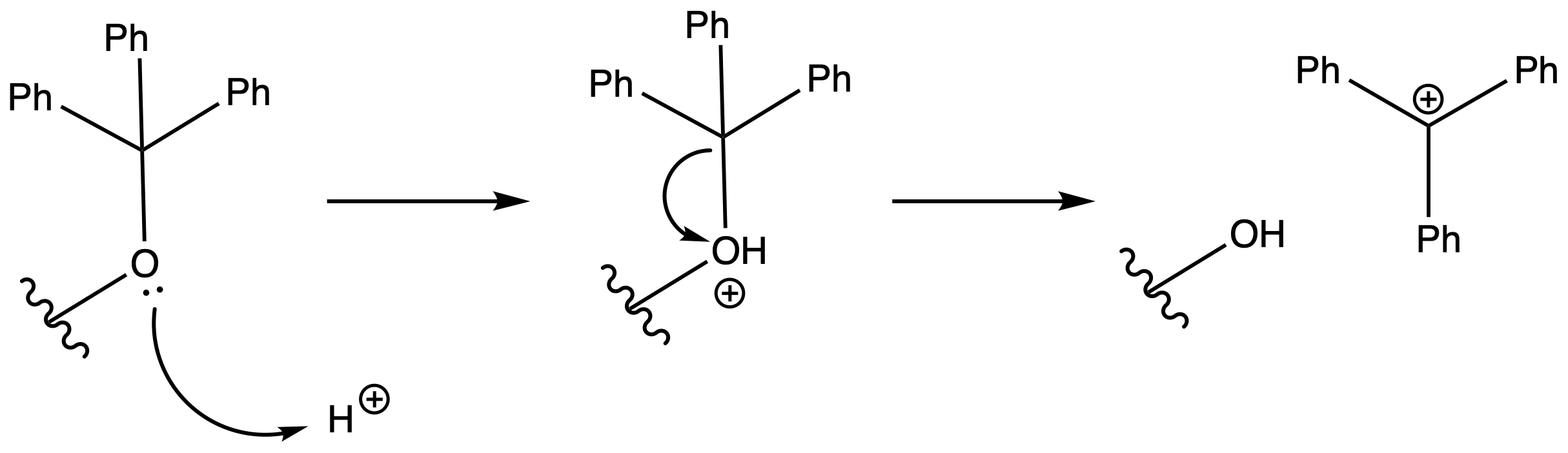

Triphenyl Eter

ProtectionReagents needed:

- Trt–Cl

Mechanism :

Deprotection

Reagents needed:

- Dilute Acid

Mechanism :

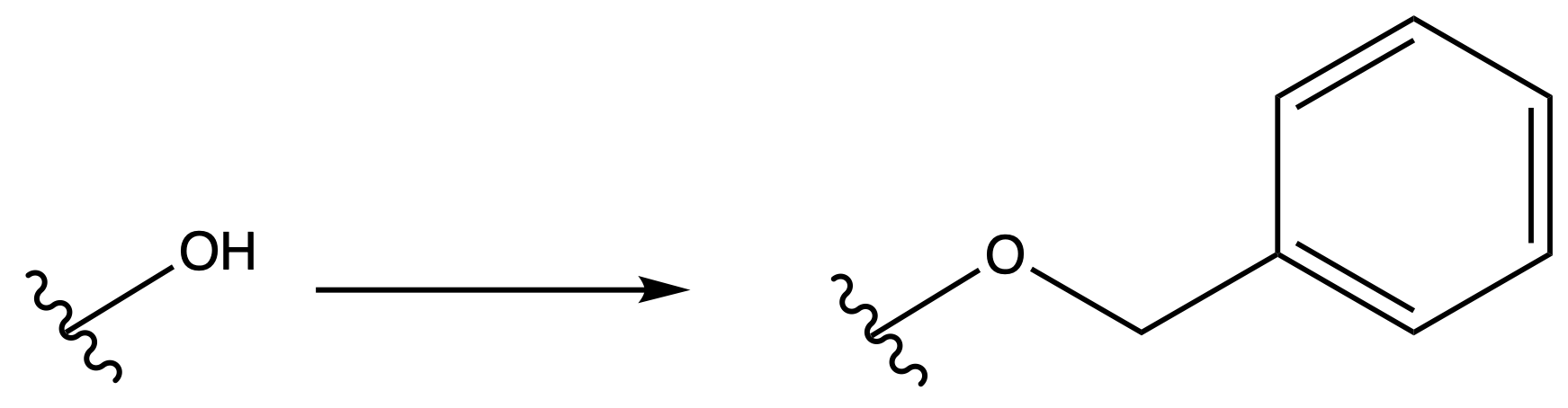

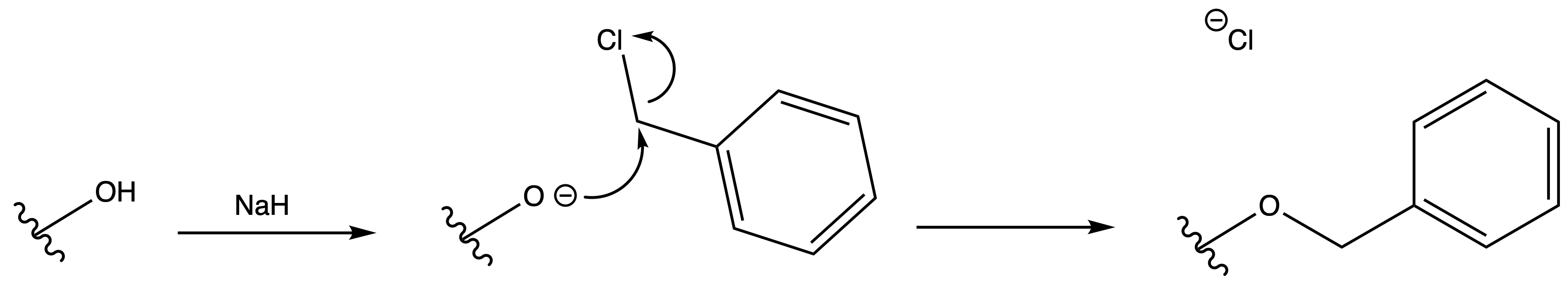

Benzyl Eter ( Bn )

ProtectionReagents needed:

- Bn–Cl + NaH

Mechanism :

Deprotection

Reagents needed:

- H2 + Pd/C

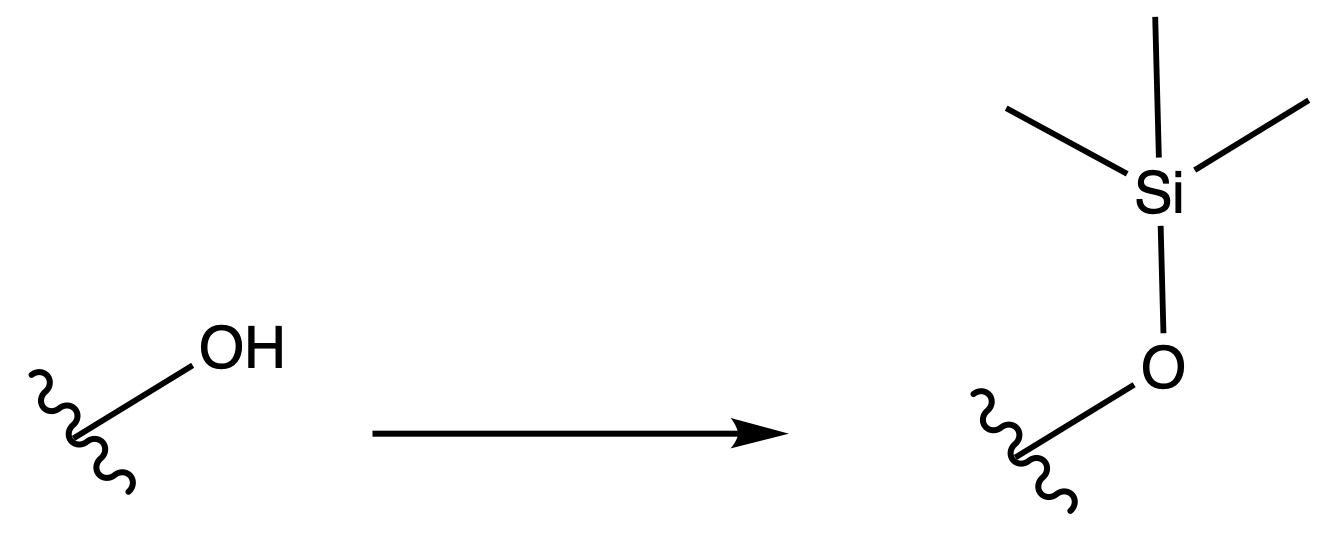

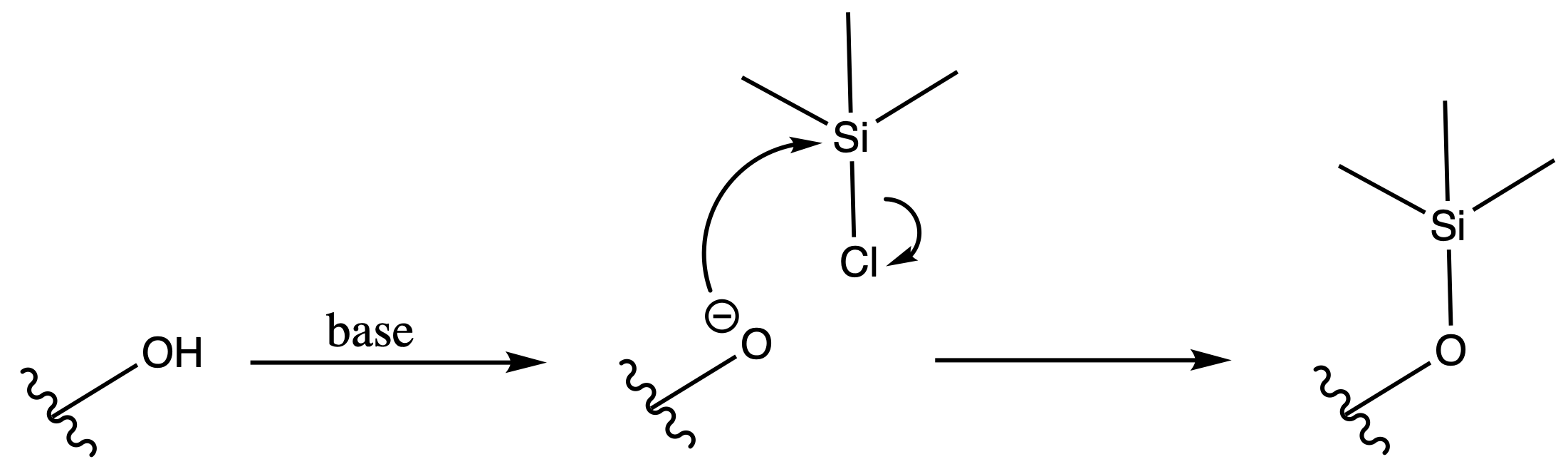

Trimethylsilyl Eter ( TMS )

ProtectionReagents needed:

- TMSCl

Mechanism :

Deprotection

Reagents needed:

- Concentrated Acid

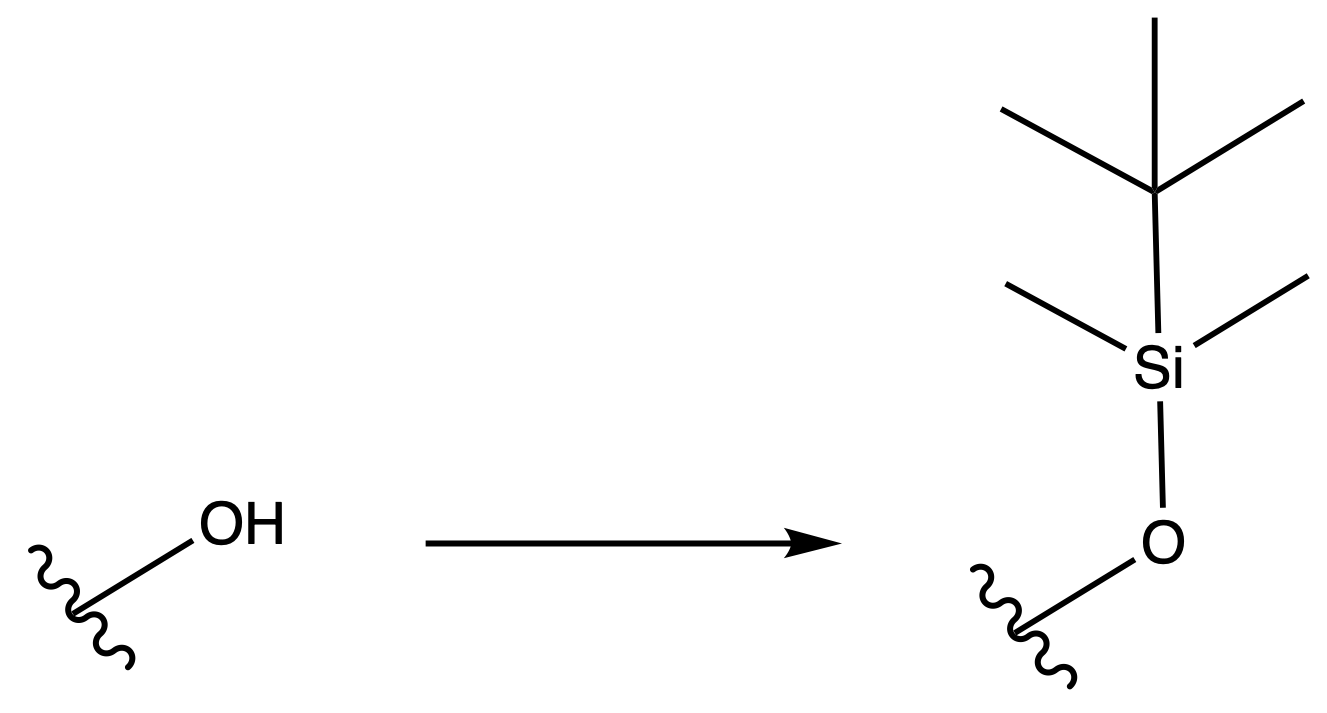

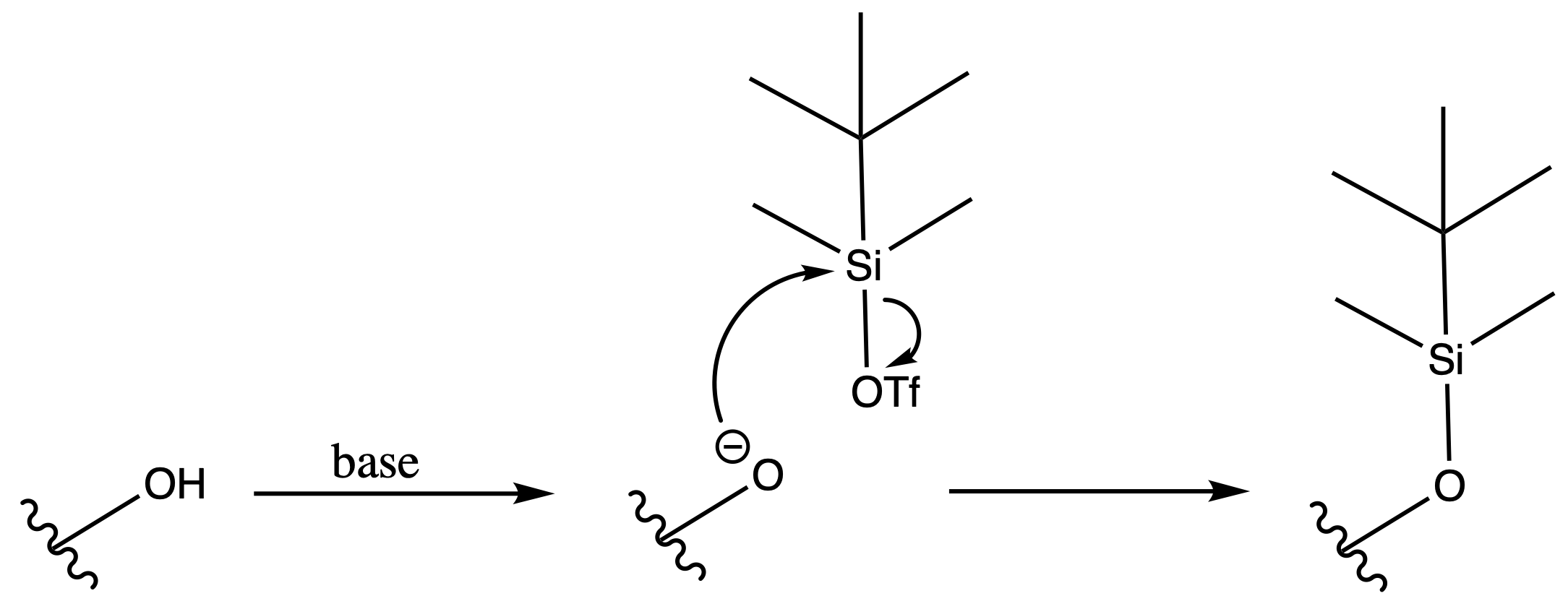

Tert-butyldimethylsilyl Eter ( TBDMS )

ProtectionReagents needed:

- TBDMS-OTf

Mechanism :

Deprotection

Reagents needed:

- Concentrated Acid

¶ Summary

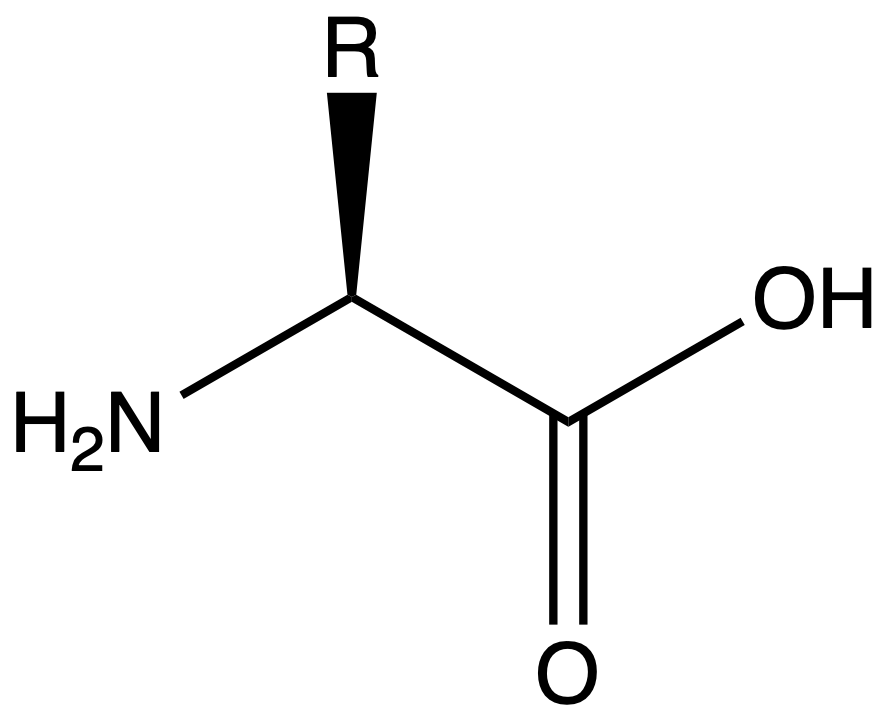

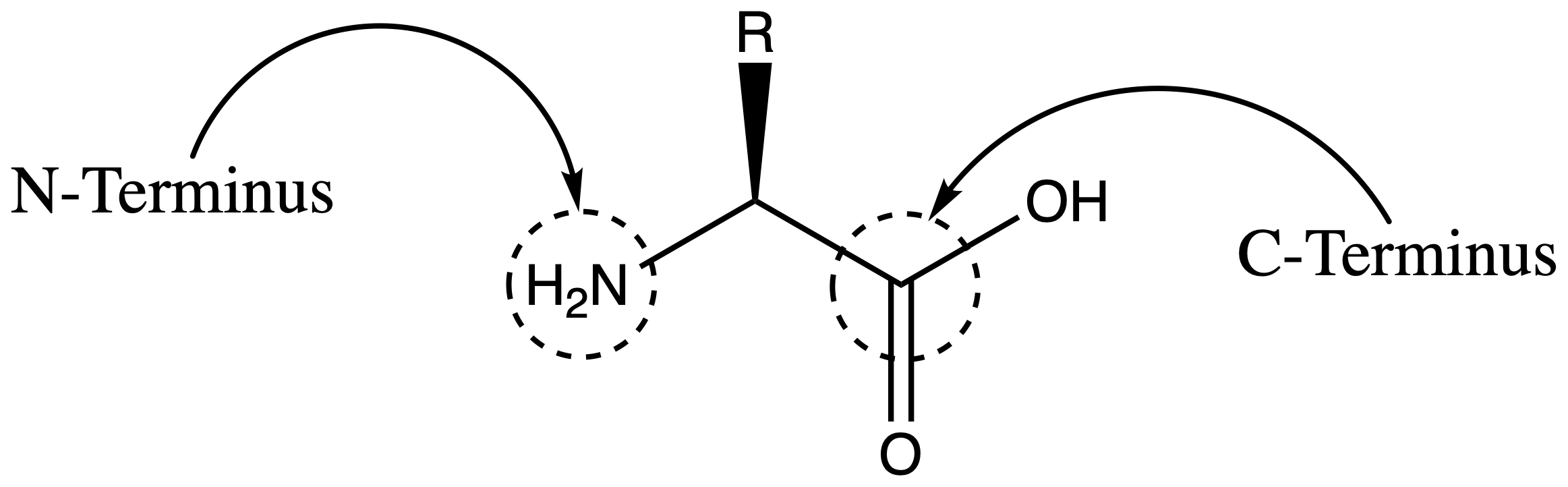

¶ Amino Acid and Peptides

Natural amino acid is a molecule with a general structure as such

- The amine group is to the carboxyl group

- The alpha carbon is either a chiral or a prochiral centre

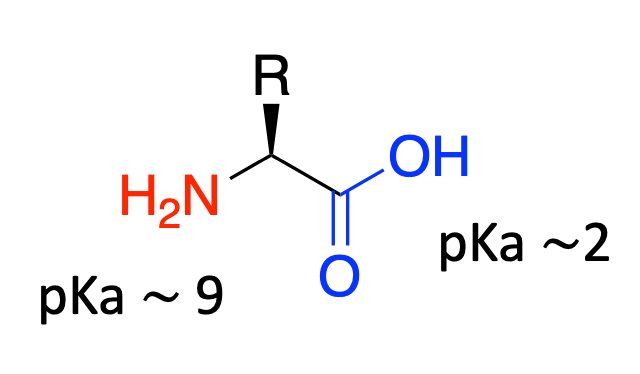

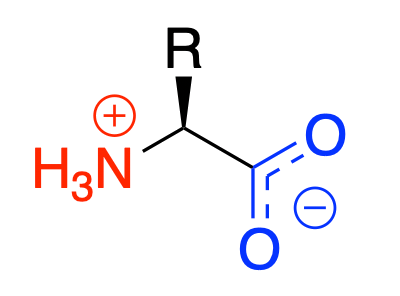

Zwitterionic

Amino acids are zwitterionic in water

- At pH 7, the amine group will be protonated and the carboxyl group will be deprotonated

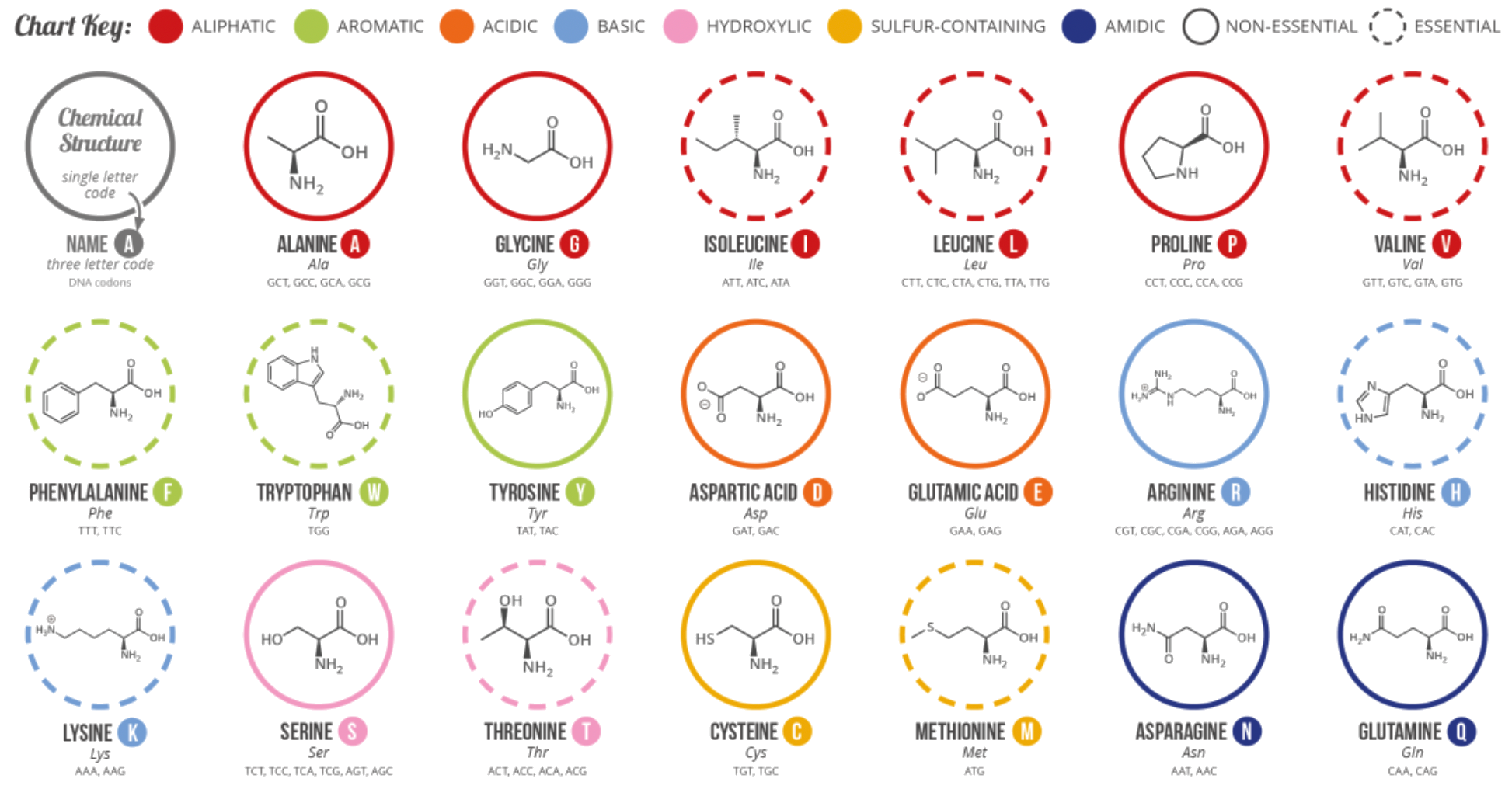

Types of Amino Acids

There are 20 different types of naturally occuring amino acids, their only differences is the group

- Depending on the group, amino acids can have different properties

- We give each of these amino acid a three-letter code and a one-letter code

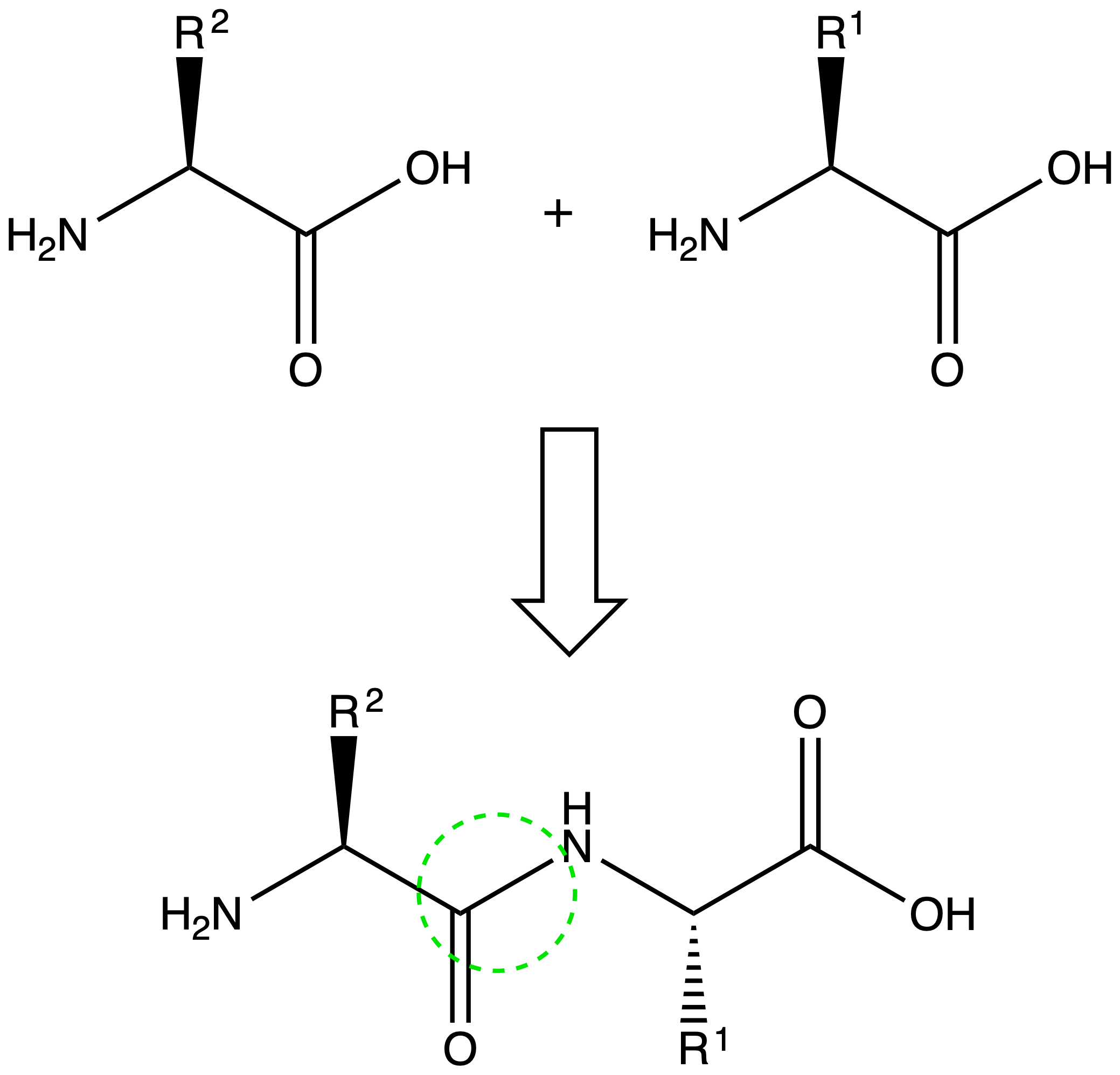

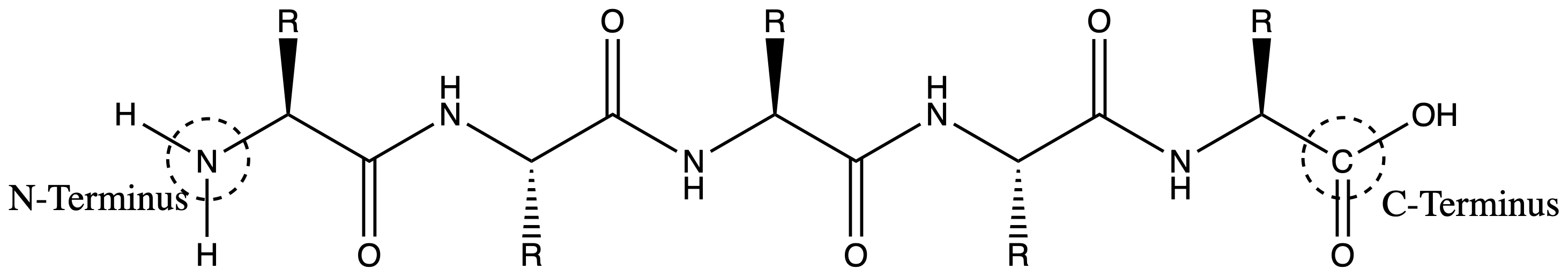

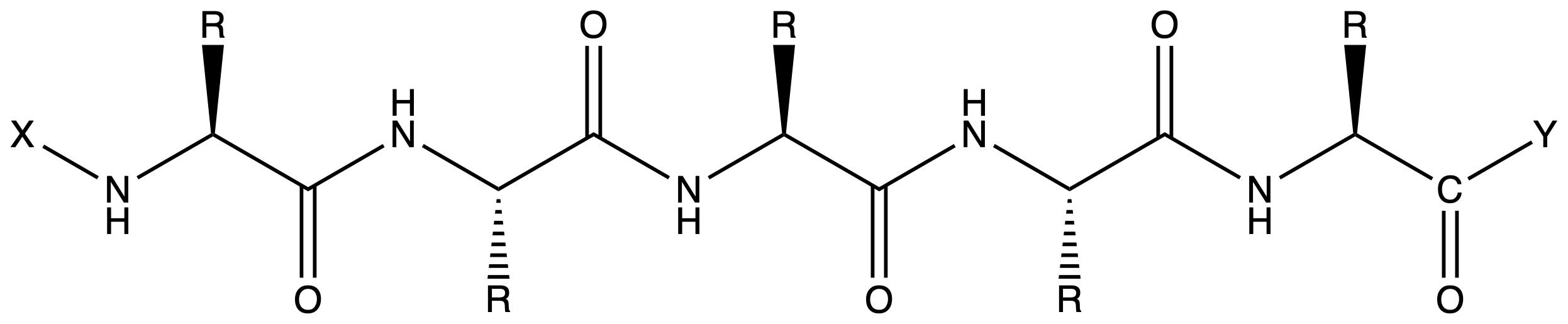

Peptides

Two amino acids join together via the formation of a peptide bond

- A peptide bond is an amide bond

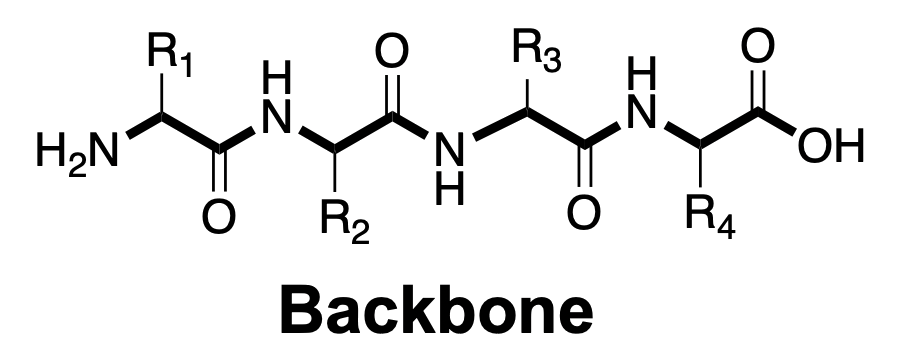

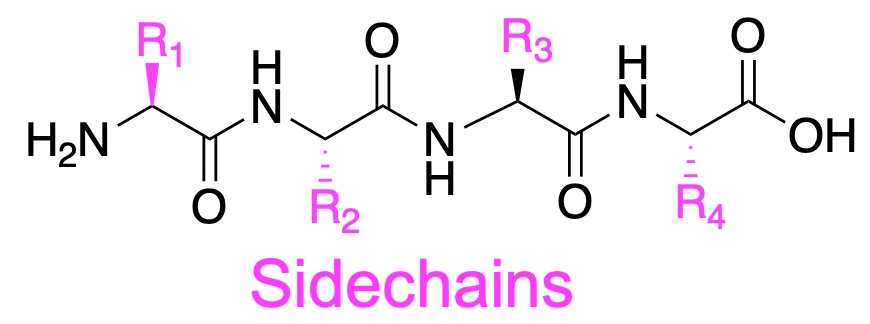

When we want to refer to different part of the peptide, we have two different words

- The backbone describes the extended chain that goes between the amine group and the carboxyl group

- The side chain describes the groups

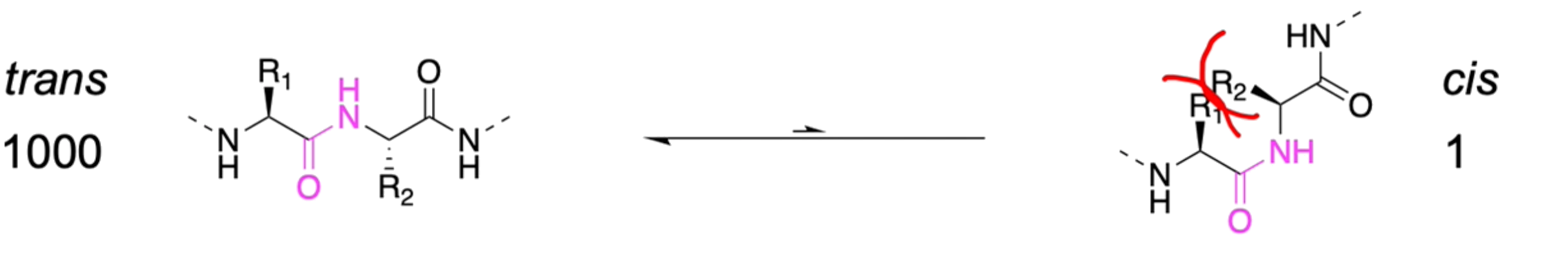

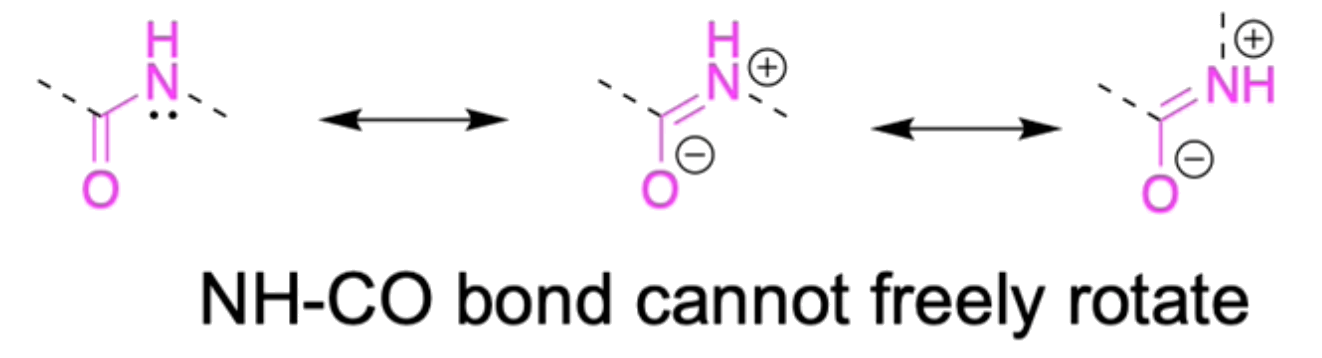

The peptide backbone is in the trans-conformation to reduce steric clashes

- Moreover, the peptide bonds cannot freely rotate since the lone pair on nitrogen is conjugated to the carbonyl, forming a partial double bond

Naming Peptides

An amino acid has two terminal, the N-terminus and the C-terminus

- A peptide therefore also has the N-terminus and the C-terminus

- The N-terminus and the C-terminus can be modified

- We name the peptide from the N-terminus to the C-terminus

¶ Synthetic Strategy of Peptides

Considerations:

- Control over identity of each amino acid

- No racemization

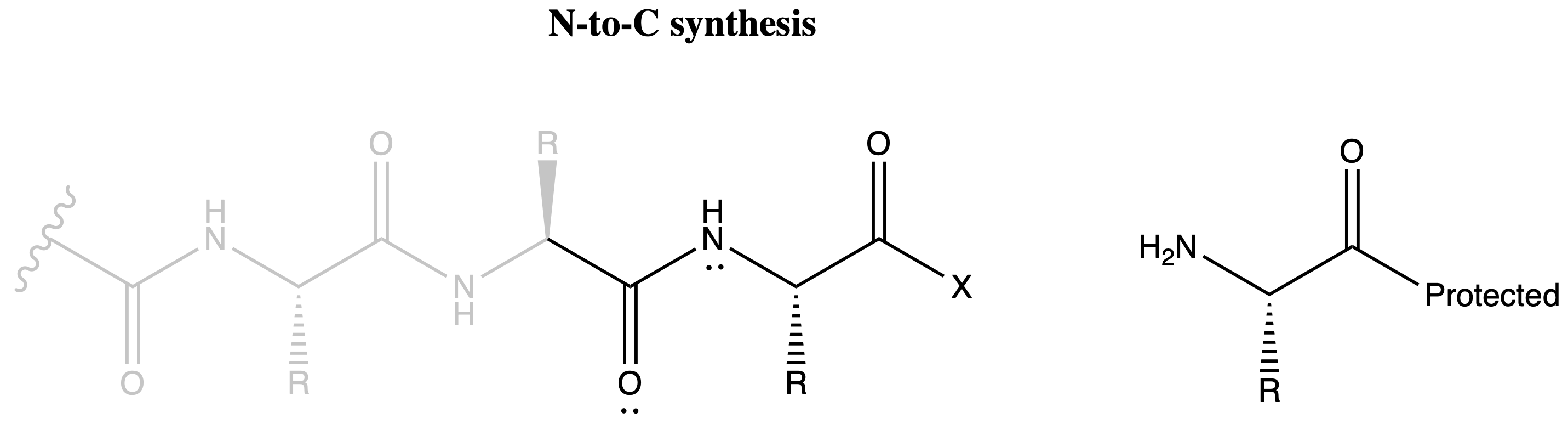

Direction of Peptide Synthesis

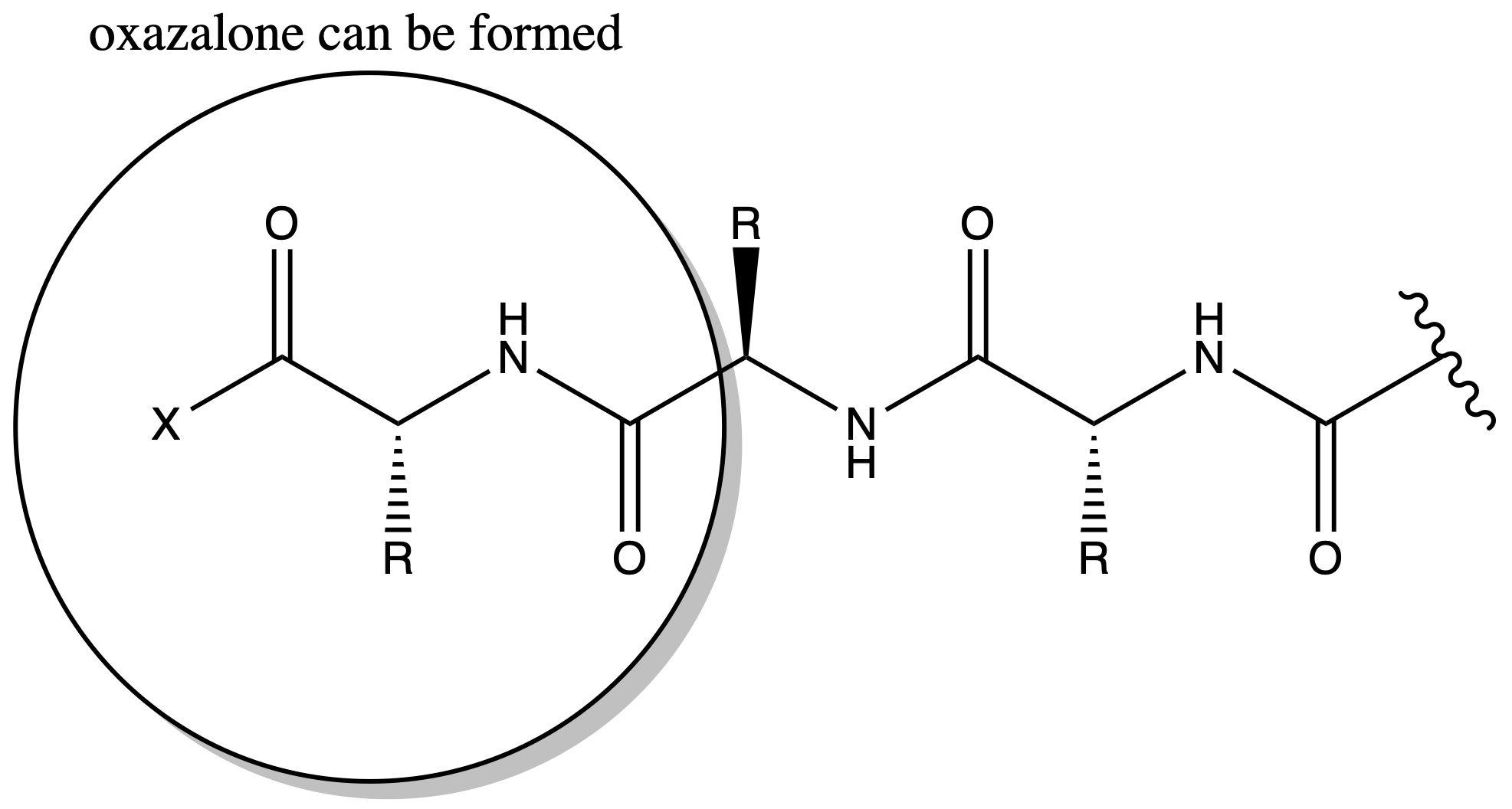

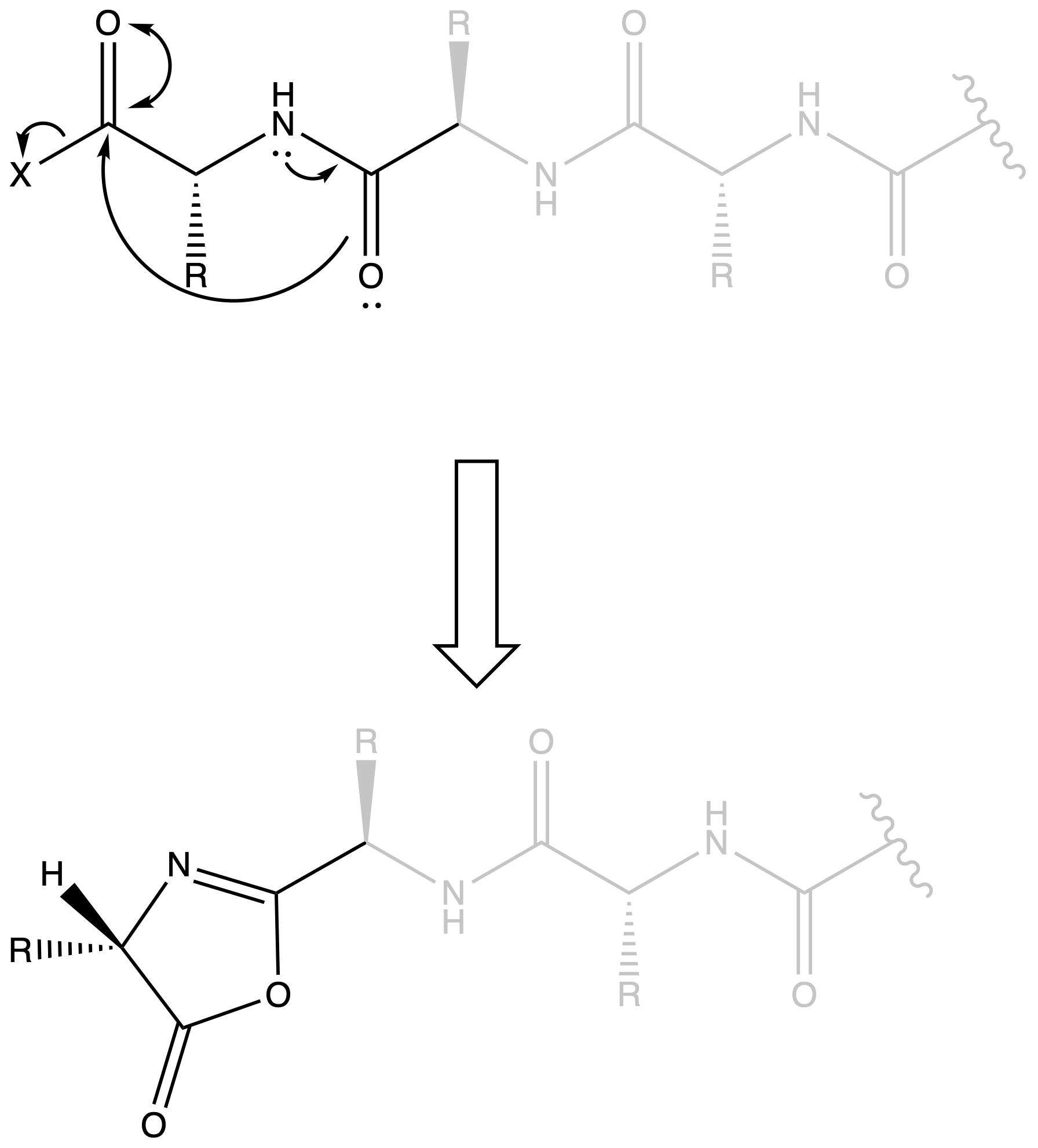

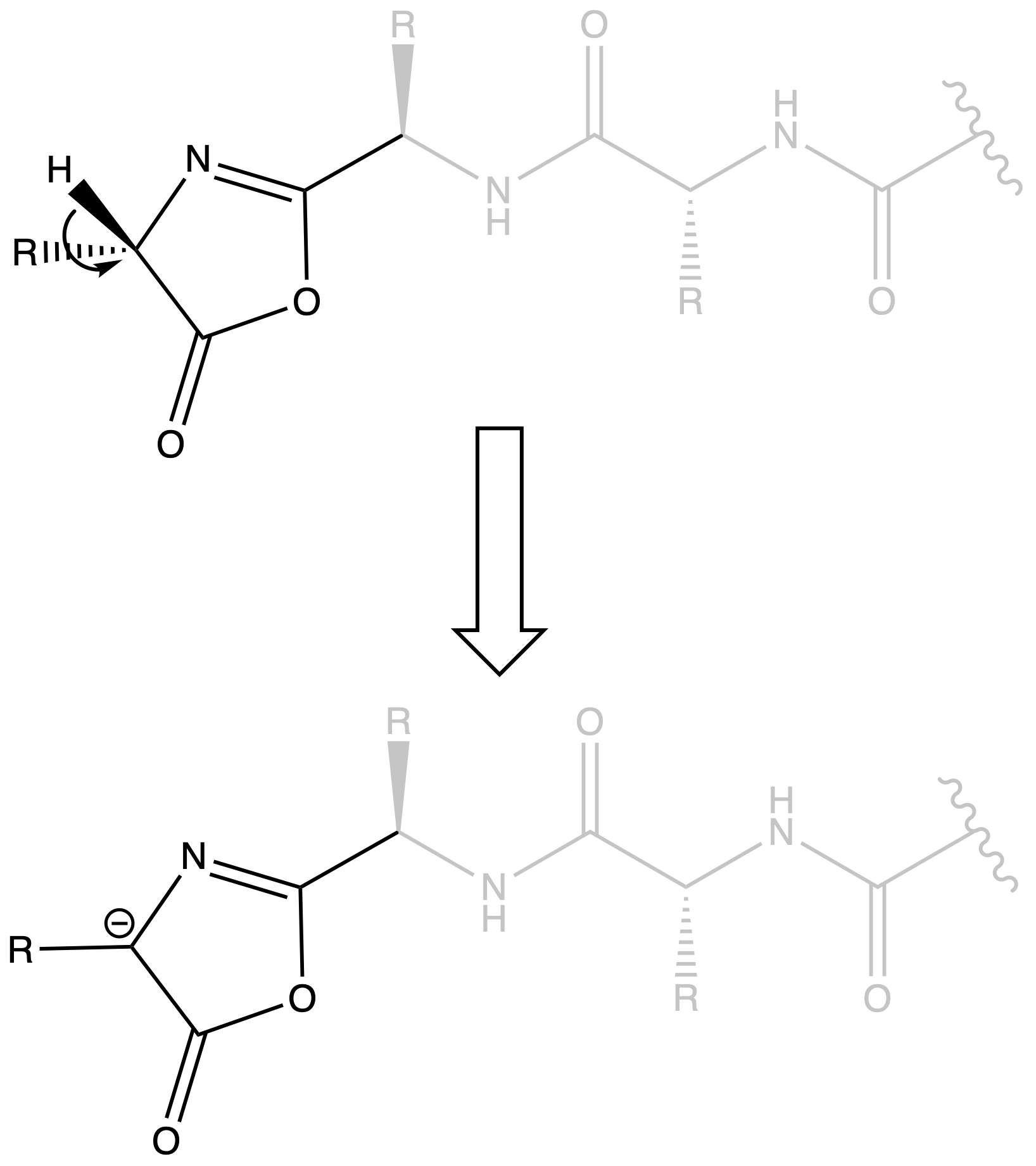

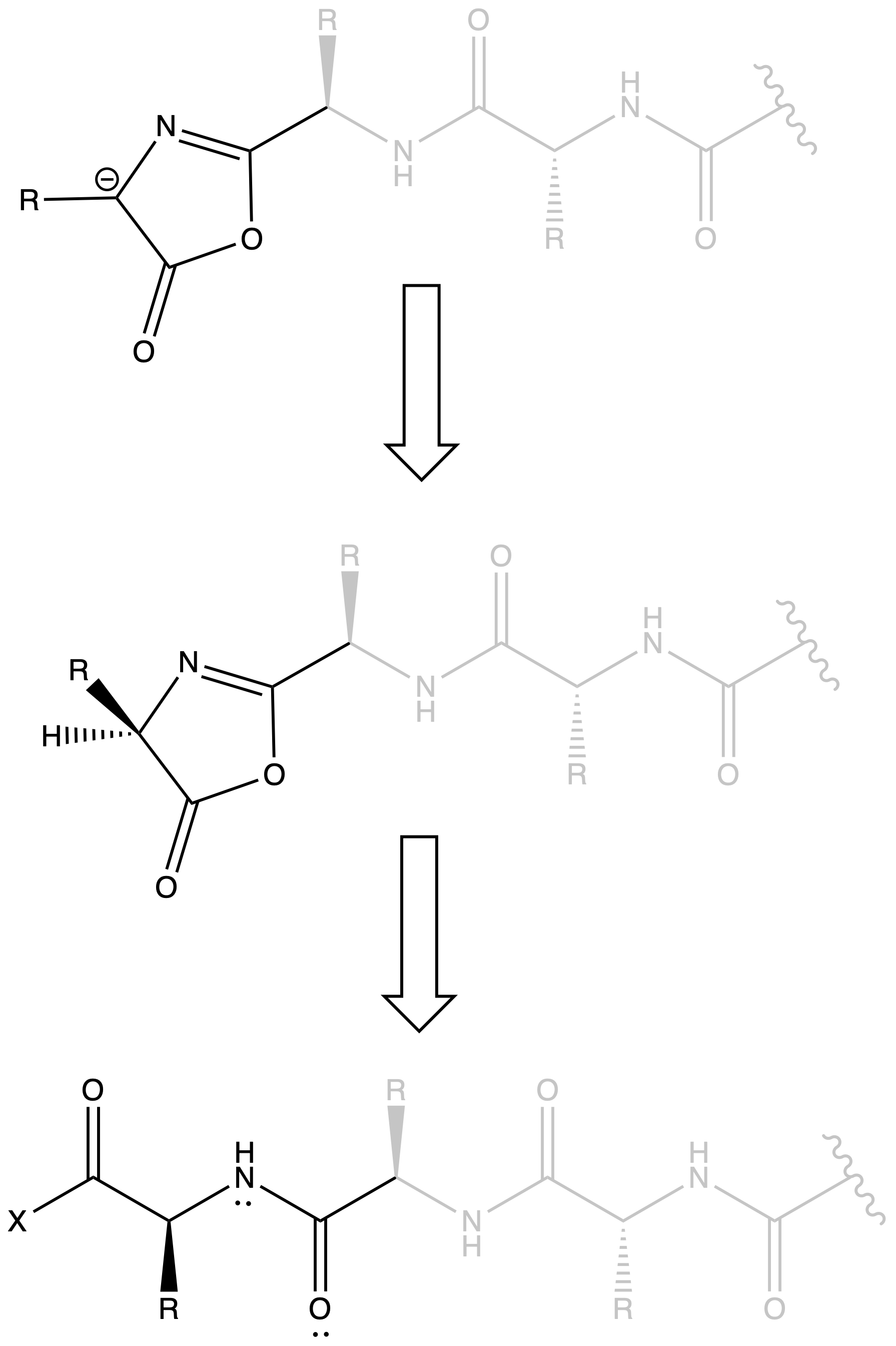

Oxazalone can result in Racemization

- When we have a peptide chain, oxalone can be formed near the terminal

- The lone pair of nitrogen is donated to the oxygen in an amide group, which means the oxygen is nucleophilic, allowing it to attack the terminal activated carboxyl group

- The hydrogen on oxazalone can be deprotonated as it will form an aromatic ring

- When the oxazalone gets protonated again, it may undergo racemization

The formation of oxazalone can be avoided if we can avoid having the amide group and the activated carboxyl group on the same molecule

- In N-to-C synthesis, both the activated carboxyl group and the amide group will be on the growing chain

- While in C-to-N synthesis, the activated carboxyl group will be on the free amino acid and the amide groups will be on the growing chain

We therefore choose the synthesize our peptides from the C-terminus to the N-terminus

Orthogonal Protecting Groups

For the backbone, we have to protect the C-terminus and the N-terminus

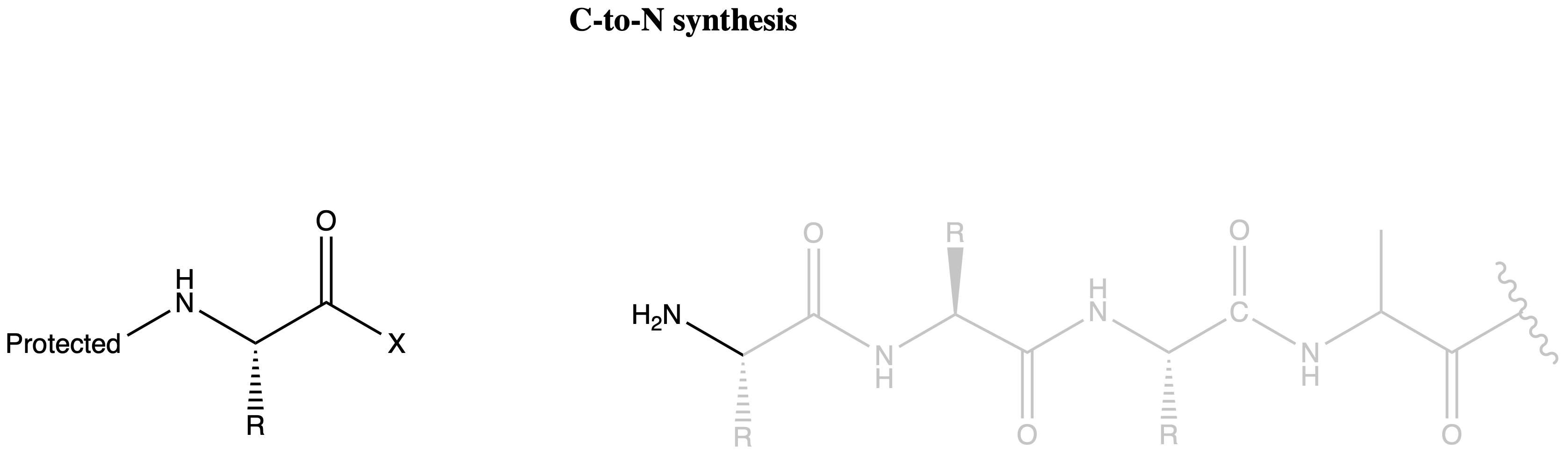

- Since we are synthesizing from the C-terminus, the C-terminus should already be linked to the resin. We choose PMB as the linker ( Wang resin ) so that it can be removed by acid at the end

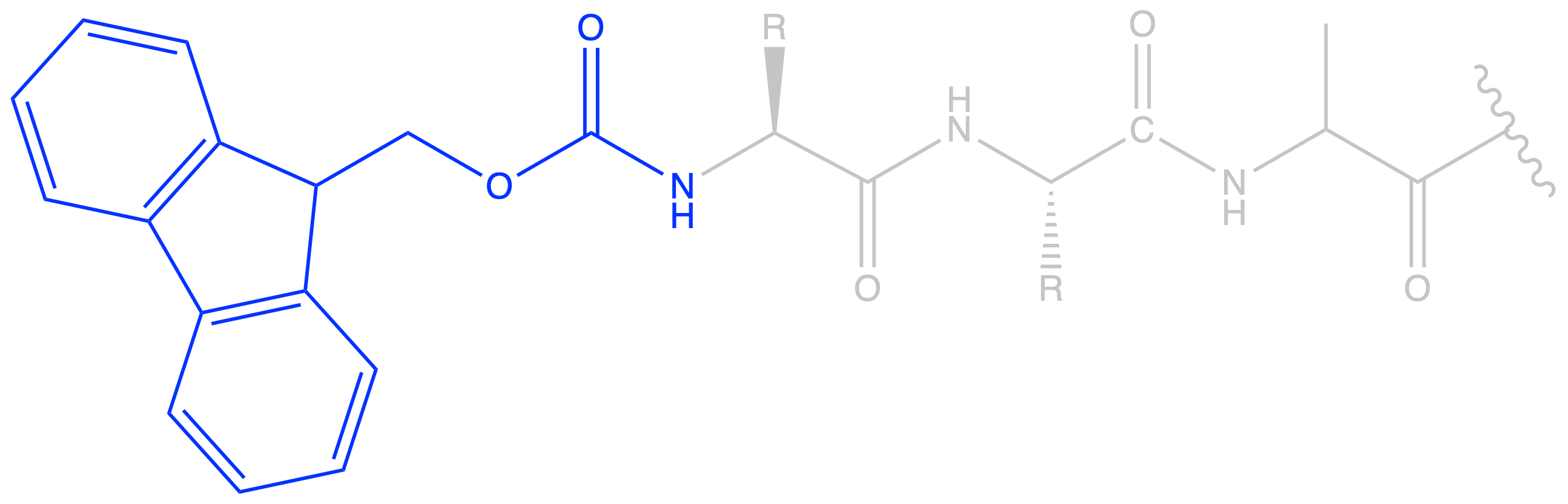

- We choose Fmoc as the protecting group for the amine as it is labile to base, making it orthogonal to PMB. Moreover, Fmoc is removed repeatedly with each round of coupling

Side chain functional groups also need protecting so they don’t interfere with coupling steps

- These should be ‘permanent’ protecting groups, meaning that they will removed only once at the end

- Notice the final step in the synthesis is removal of the peptide from the resin

- Ideally you want to minimise reaction steps, so this same step should also remove all side chain protecting groups

- Therefore you will want acid labile side chain protecting groups

Amide Bonds Formation

We need to activate the carboxyl group if we want amine to attack it

- You might first think of using an acid chloride, but this can be challenging as conditions to form this tend to be quite harsh and often incompatible with amino acid protecting groups

- Acid chlorides can also be too reactive and lead to side products

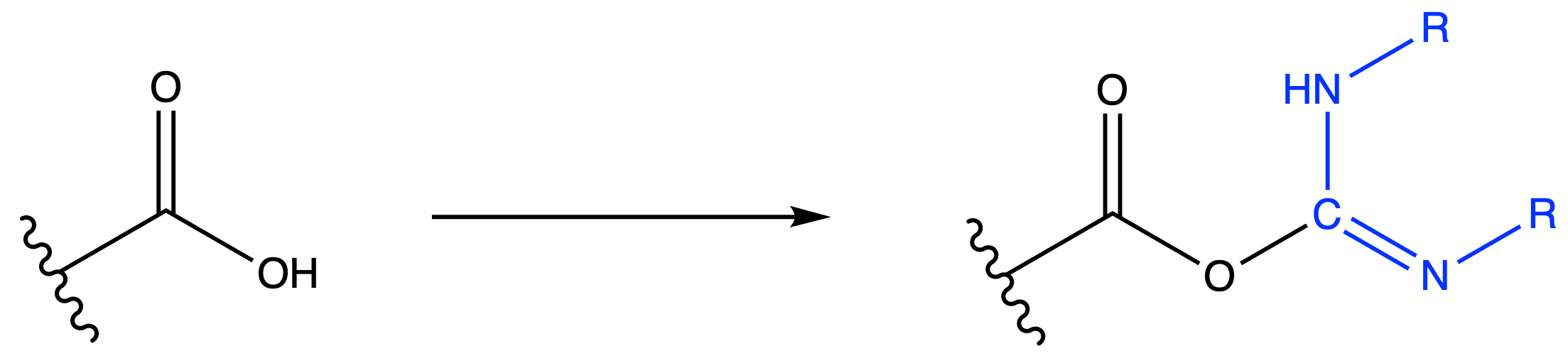

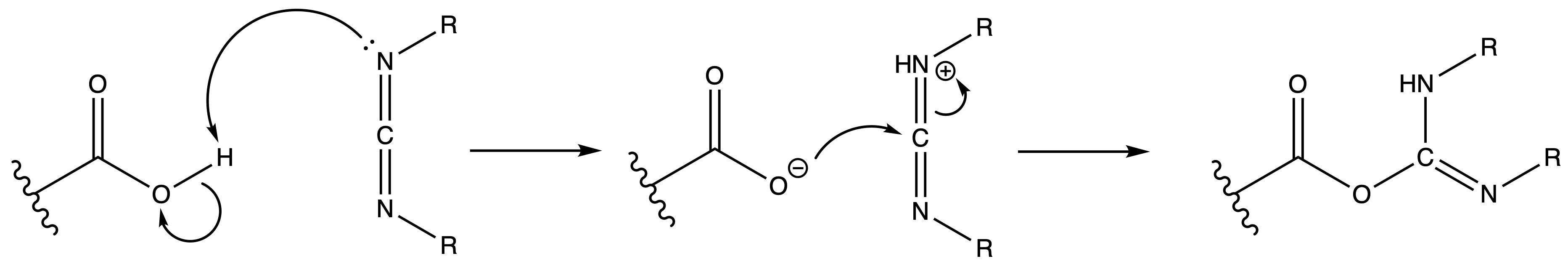

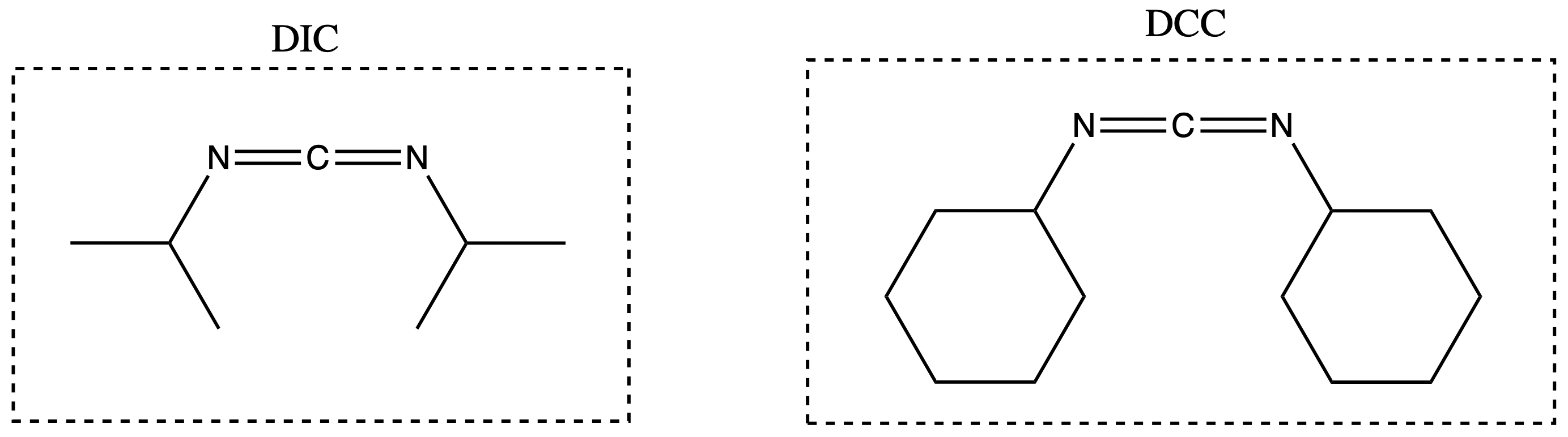

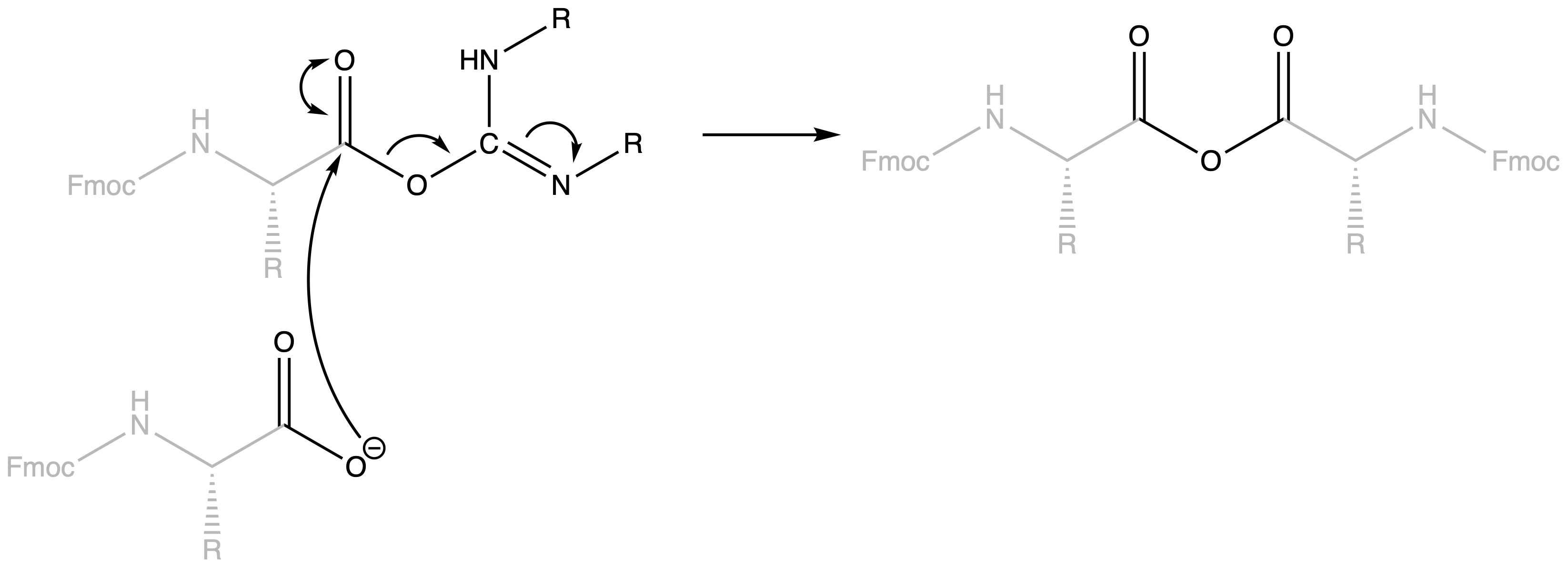

We instead use Carbodiimide coupling reagents to activate it

- Mechanism:

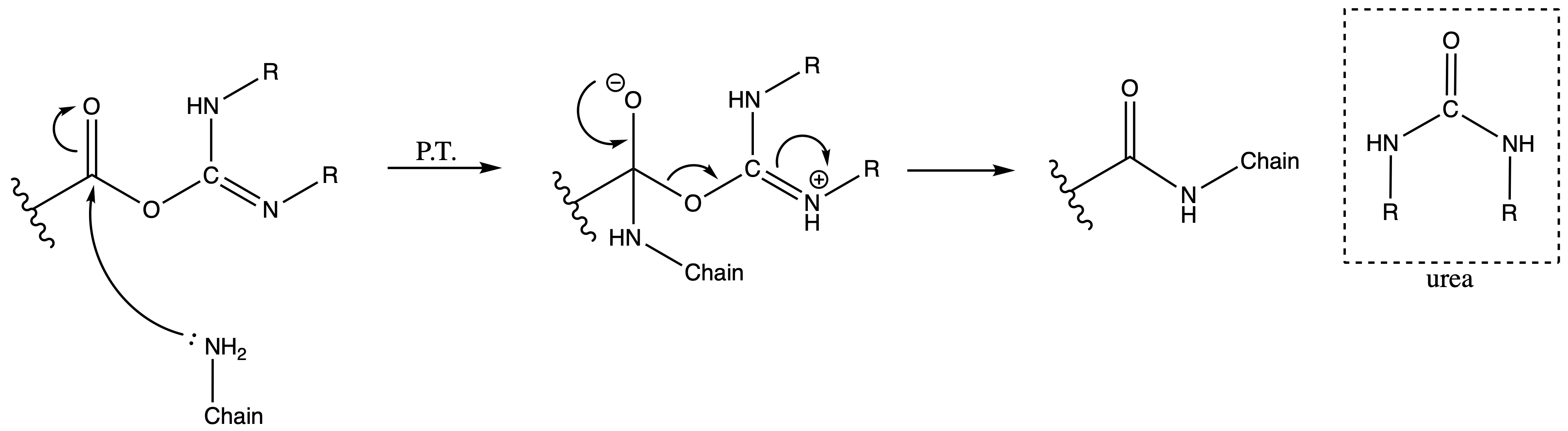

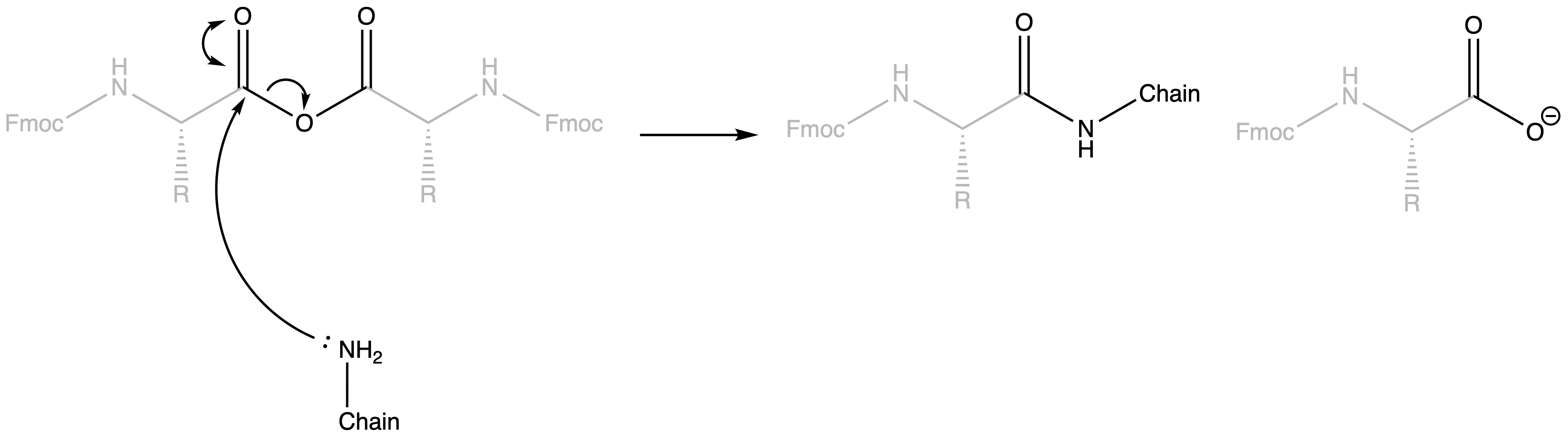

The activated carboxyl group can then form amide bonds

- Mechanism :

The group on the Carbodiimides is also important

- If = cyclohexyl, the urea precipitates. If = isopropyl, the urea stays soluble

- Insoluble biproduct helps drive reaction which is good for solutions phase reaction, but precipitate is bad for solid phase reaction so DIC is usually used

Unwanted side reactions can happen when we activate the group with carbodiimides

- Anhydride can be formed in the process

- Anhydride is quite reactive, so amide will still be formed subsequently

- However, this little maneuver will cost us 2 eq. acid per amide bond

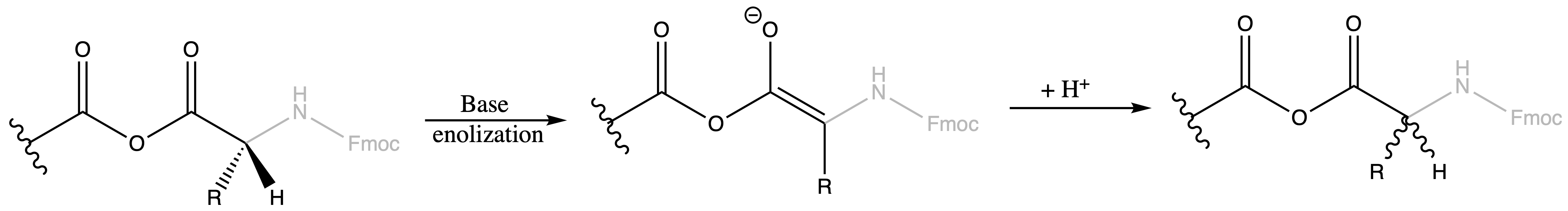

- Moreover, we can also get racemisation by removal of the alpha-proton

Anhydride formation and amino acid racemisation can be reduced by tuning the reactivity of the isoacyl urea intermediate

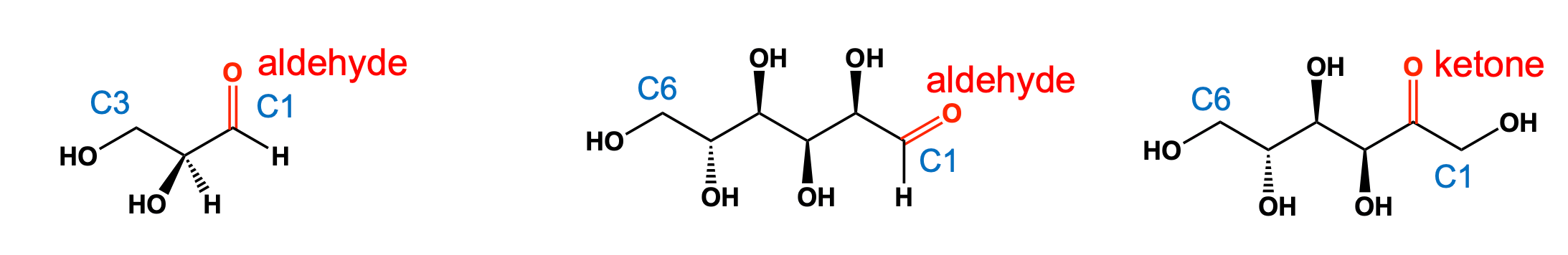

¶ Carbohydrates

Carbohydrates are polyhydroxy aldehydes or ketones or compounds that yield such entities upon hydrolysis

- Numbering: C1 closest to aldehyde/ketone

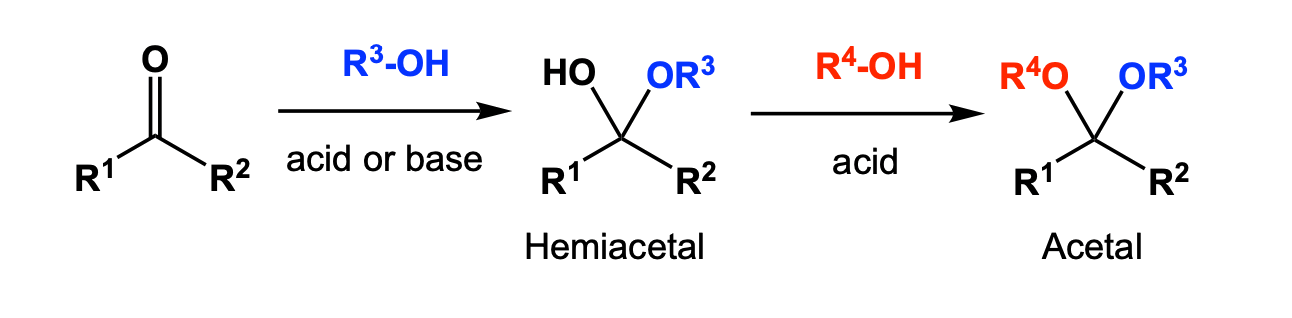

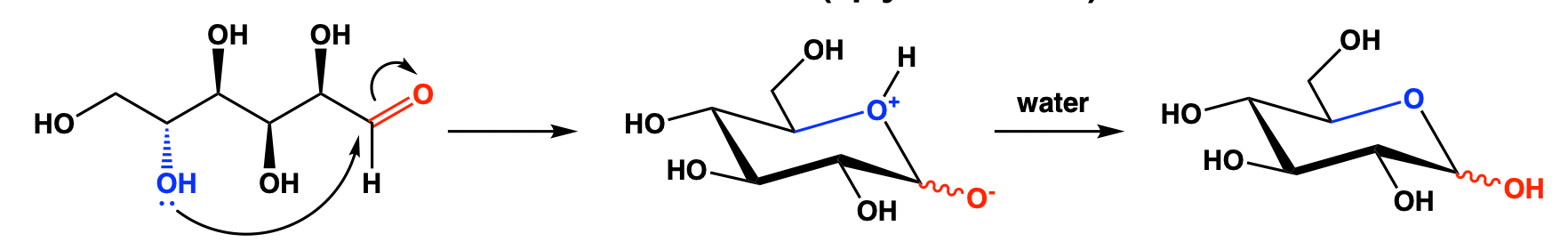

¶ Cyclic Carbohydrates

Carbohydrates are often cyclic

- Carbonyls can be converted to Hemiacetal and Acetal

Mechanism:

Carbohydrates often contain both carbonyl and hydroxyl groups, so they can undergo self-cyclisation